Basic Info.

Model NO.

EPT-I042R

Classification

Hybrid Insulation Materials

Color

Natural Clear

Brand

Ept

Other Application

Office Machinery,Printing,Dyeing Machinery

Usege

Insulation and Protection

Purpose

Electric and Electrical Project

Performation

with Good Heat Shrink Performance

Transport Package

Carton Box

Specification

customized

Trademark

EPT

Origin

China

HS Code

39173200

Production Capacity

5000 Meters/Day

Product Description

FEP Is one of the Fluoropolymer material that with Excellent Performance. It has Outstanding Chemical/Electrical & Physical Properties. We provide both FEP normal non shrinkable tubing and FEP shrinkable tubing .

FEP Heat Shrink tubing is widely used in different kind of fields :

Office machinery roller

Paper making machinery

Printing machinery

Color dyeing machinery

Motors

Lighgting industry

Cable jacket & cable joint

protection from corrosive environments

electric insulation for electric home applaince

medical machine

Features of FEP Heat shrink Tube:

Starting shrinking temperature is 110 ºC

Low/High Temperature resistant: -200--200ºC

Non-Sticky,

Non flammability,it will not flame in the air, Oxygen index>95VOL%

Anti-Corrusion

Hight Electrical reliability,and good insulation ability

Dielectric constant viscosity is 2.1under 60HZ-60MHZ

Volume resistance>10 18ΩM,Surface resistance>10 13Ω,Arc Resistance>165 second,No electricity leakage.

For the FEP heat shrink tube, we are able to provide 1:1.3 FEP shrink ratio heat shrink tube ,

Size we can privide before shirked : Dia2mm to 185mm

All our product is compliant with RoHs standard and halogen free.

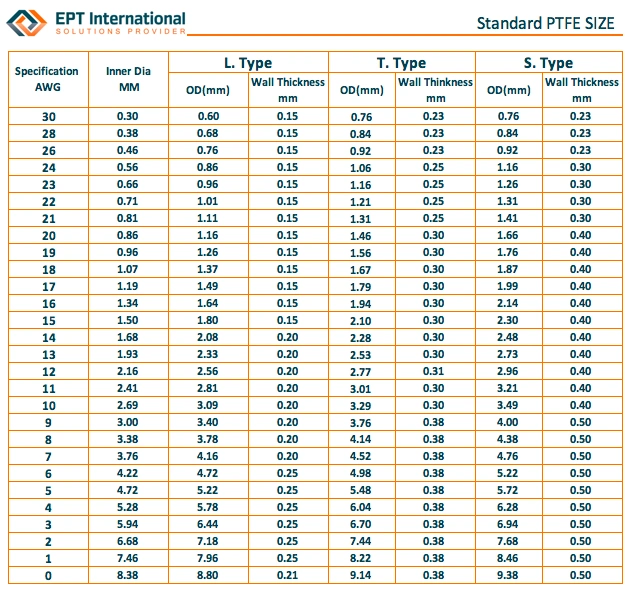

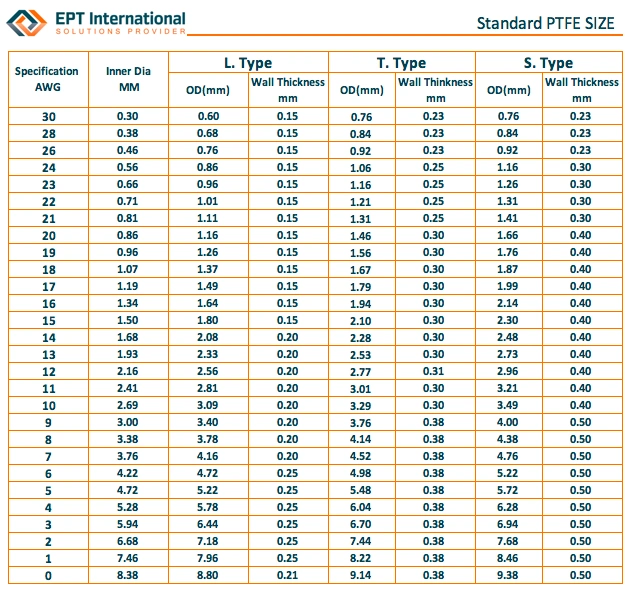

Below are some of our standard size chart, but we are able to do OEM specification :

If you need any FEP tubing ,pls contact us.

PTFE Heat Shrink Tube

PTFE Heat Shrink Tube

Technical Data Sheet

FEP Heat Shrink tubing is widely used in different kind of fields :

Office machinery roller

Paper making machinery

Printing machinery

Color dyeing machinery

Motors

Lighgting industry

Cable jacket & cable joint

protection from corrosive environments

electric insulation for electric home applaince

medical machine

Features of FEP Heat shrink Tube:

Starting shrinking temperature is 110 ºC

Low/High Temperature resistant: -200--200ºC

Non-Sticky,

Non flammability,it will not flame in the air, Oxygen index>95VOL%

Anti-Corrusion

Hight Electrical reliability,and good insulation ability

Dielectric constant viscosity is 2.1under 60HZ-60MHZ

Volume resistance>10 18ΩM,Surface resistance>10 13Ω,Arc Resistance>165 second,No electricity leakage.

For the FEP heat shrink tube, we are able to provide 1:1.3 FEP shrink ratio heat shrink tube ,

Size we can privide before shirked : Dia2mm to 185mm

All our product is compliant with RoHs standard and halogen free.

Below are some of our standard size chart, but we are able to do OEM specification :

If you need any FEP tubing ,pls contact us.

PTFE Heat Shrink Tube

PTFE Heat Shrink Tube Technical Data Sheet

| ITEM | TESTING METHOD | PARAMETERS |

| Specific Gravity | ASTM D7923 | 2.16 |

| Tensile Strength | ASTM D638 | 31 Mpa |

| Deuteronomy | ASTM D638 | 305% |

| Bending Coefficient | ASTM D790 | 586 Mpa |

| Impact Strength | ASTMD256+23 ºC-54 ºC J/m | 155 |

| Hardness | ASTM D2240 | 57 |

| Friction Coefficient | 0.2 | |

| Melting Point | 327ºC | |

| Use Temperature | -60ºC+260ºC | |

| Inflammability | 94V-0 | |

| Dielectric Coefficient | ASTM D150 | 2.1 |

| Dissipation factor | ASTM D150 | 0.0002 |

| Arc Coefficient | ASTM D495 | >300 |

| Intrinsic volume resistivity | ASTM D257 | >1018Ω MM |

| Solvent Resistance | ASTM D543 | Good |

| Chemical Resistance | ASTM D543 | Good |