- Overview

- Product Description

- Product Parameters

- Company Profile

- Packaging & Shipping

Basic Info.

Product Description

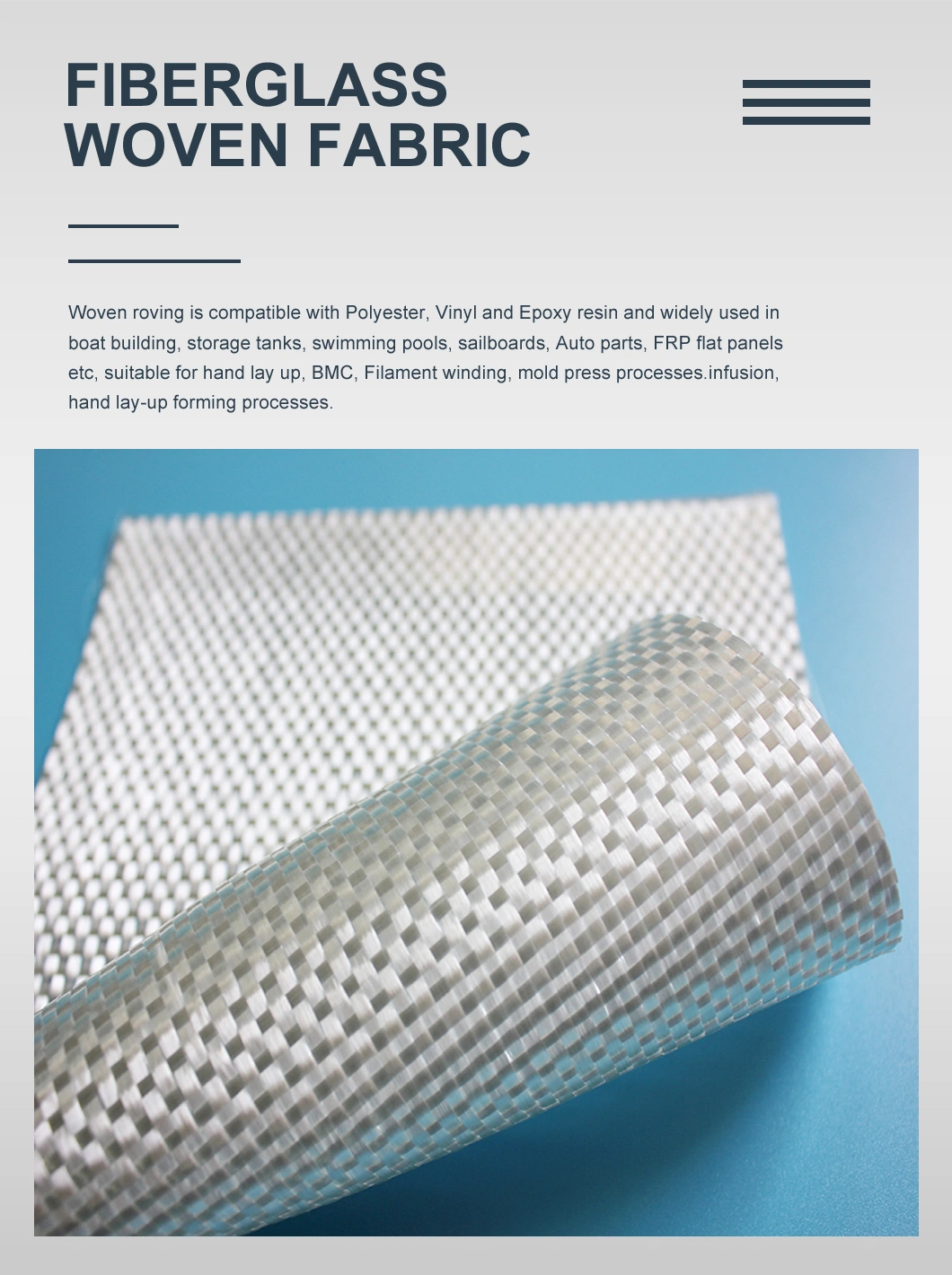

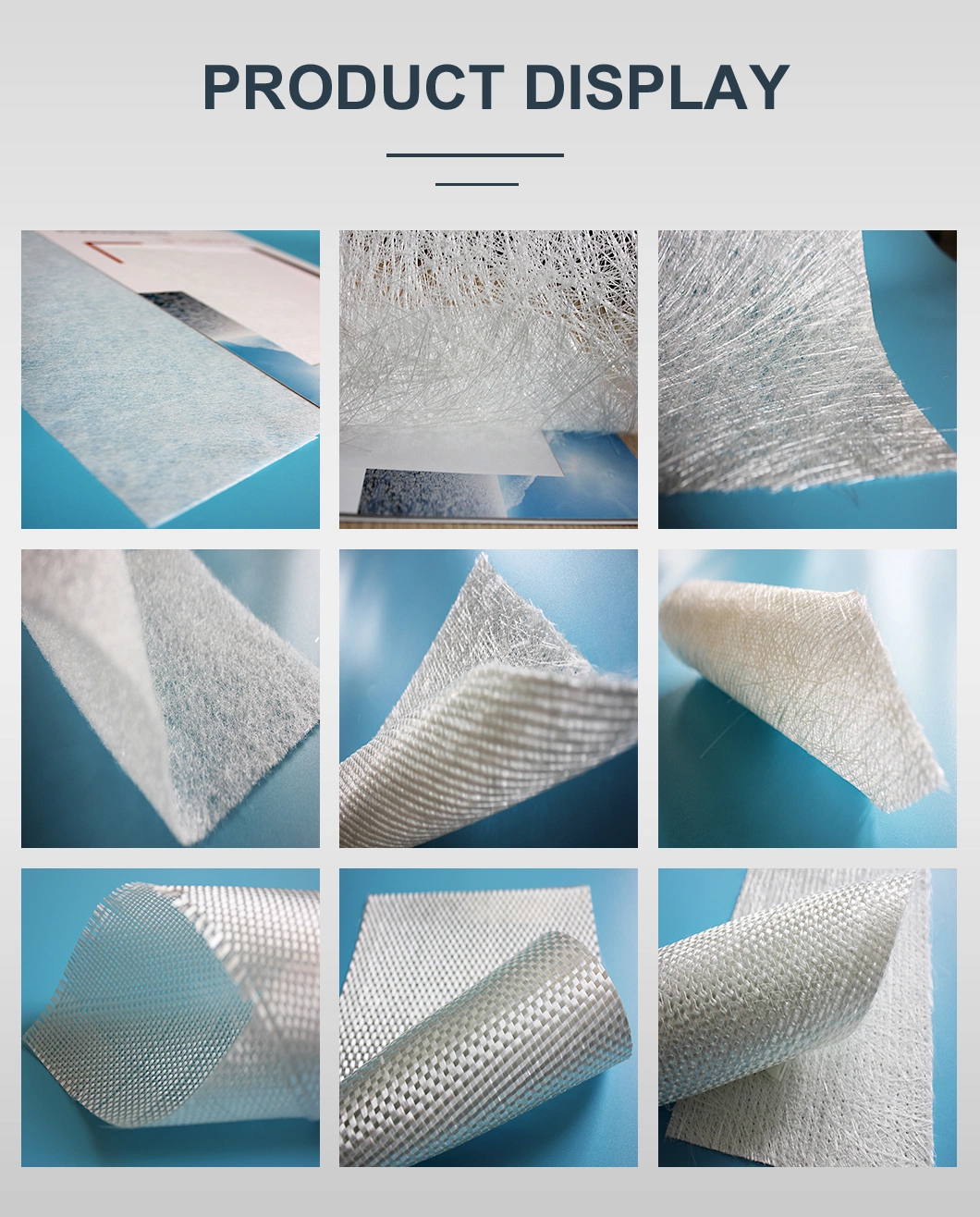

Woven roving is compatible with Polyester, Vinyl and Epoxy resin and widely used in boat building, storage tanks, swimming pools, sailboards, Auto parts, FRP flat panels etc, suitable for hand lay up, BMC, Filament winding, mold press processes.

A: Woven Roving(E\ECR)

A: Woven Roving(E\ECR) | Code | Glass type | Weight (g/m2) | Weave | Moisture Content | L.O.I Content | ||

| Breaking strength | |||||||

| Warp | Weft | ||||||

| RULR200 | E/ECR | 200 | 1300 | 1100 | Plain | ≤0.2 | 0.4-0.8 |

| RULR270 | E/ECR | 270 | 1900 | 1700 | Plain | ≤0.2 | 0.4-0.8 |

| RULR300 | E/ECR | 300 | 2000 | 1800 | Plain | ≤0.2 | 0.4-0.8 |

| RULR360 | E/ECR | 360 | 2200 | 2000 | Plain | ≤0.2 | 0.4-0.8 |

| RULR400 | E/ECR | 400 | 2500 | 2200 | Plain | ≤0.2 | 0.4-0.8 |

| RULR500 | E/ECR | 500 | 3000 | 2750 | Plain | ≤0.2 | 0.4-0.8 |

| RULR530 | E/ECR | 530 | 3300 | 3000 | Plain | ≤0.2 | 0.4-0.8 |

| RULR580 | E/ECR | 580 | 3600 | 3300 | Plain | ≤0.2 | 0.4-0.8 |

| RULR600 | E/ECR | 600 | 4000 | 3850 | Plain | ≤0.2 | 0.4-0.8 |

| RULR800 | E/ECR | 800 | 4600 | 4400 | Plain | ≤0.2 | 0.4-0.8 |

| RULR1000 | E/ECR | 1000 | 5300 | 5100 | Plain | ≤0.2 | 0.4-0.8 |

B: Woven Roving Combo Mat

1.Product Description

Woven Roving Combo Mat is compatible with polyester, vinylester,epoxy and phenolic resine.

The product is widely used in pultrusion, hand lay-up and RTM processes.

The product is used most widely in the boat industry and the typical end-use applications include FRP boat hulls, automotive housings and doors, laminates, cooling and stnictural shapes.

2. Specifications

Woven Roving Combo Mat is a complex mat made by stidching together woven rovjng and a layer of evenly distributed chopped strands.

3.Product List

| Product | Gless | Woven Roving g/m2 | Chopped Strands | Overall/Density g/m2 |

| EMK600/225 | E | 600 | 225 | 825 |

| EMK600/300 | E | 600 | 300 | 900 |

| EMK600/450 | E | 600 | 450 | 1050 |

| EMK800/225 | E | 800 | 225 | 1025 |

| EMK800/300 | E | 800 | 300 | 1100 |

| EMK800/450 | E | 800 | 450 | 1250 |

1.Roll width: Standard width in 1000mm,1270mm, and other sizes depends on customer's real needs, available in 200mm to 3200mm.

2.Packing: Fiberglass woven roving is usually rolled in a paper tube with inner diameter 76mm. The roll is warped with plastic film, then put into carton. Lay the rolls horizontally, and can be loaded on pallets and bulk in container.

3.Storage: The product should be stored in a cool, water-proof area. It is recommended that the room temperature and humidity be always maintained at 15ºC to 35ºC and 35% to 65% respectively. Please keep the product in its original packaging before being used, avoiding moisture absorption.

C: Sandwich Fabric Complex Mat

Product Description

Sandwich Fabric Complex Mat is compatible with polyester, vinylester, epoxy and phenolic resins.

The product is widely used in hand lay-up, RTM processes and reinforcement for closed mould process.

The product is used most widely in the boat and the automotive industry, the typical end-use applications include FRP boat hulls , automotive housings and doors, laminates .cooling .apparatus and structural shapes.

2. Product features

3. Specification

| Type | Width nun | Roving or csm g/m2 | Core g/m2 | Csm g/m2 | Total weight g/m2 |

| <W) S300-V180-S300 | 1250*2600 | 300 | 180 | 300 | 780 |

| <W) S300-V250-S300 | 1250-2600 | 300 | 250 | 300 | 850 |

| <W) S450-V180-S450 | 1250-2600 | 450 | 180 | 450 | 1080 |

| <W) S450-V250-S450 | 1250-2600 | 450 | 250 | 450 | 1150 |

| <W) S600-V180-S600 | 1250-2600 | 600 | 180 | 600 | 1380 |

| (W) S600-V250-S600 | 1250-2600 | 600 | 250 | 600 | 1450 |

D: Stitch-Bonded Glassfiber Fabric

1. Properties

Stitch-bonded glassfiber fabric is a new type of multiplayer composite reinforcement in which each layer of glassfiber roving is arranged single-directionally and parallelly in the direction of 0 and 90 degrees with the outermost layer cornsisting of chopped strands if necessary. Then the whole system is needled together by stitch threads to from needled mats, warp-knitted woven rovings, composite mats, etc., according to their different texture . The biggest width is 2600mm, it can be cutted according to demand of the consumer.

Without intersections of weft and warp , this non-crimp products is characterized by its optimal mechanical performance, excellent resin impregnation , easy workability and low cost. It is also named Non-Crimp Fabric. It is suitable for manufacturing FRP boat hulls , automobile bodies , pipes , chemical containers, profiles , laminates , etc,, especially suitable for the products moulded by mechanical processes such as RTM and pultrusion and winding

2. Specification

| Specifications | Weight of Yarn g/m* | Weight of Mat g/nf | Total Weight g/m* | Speed of | Flex Strength Mpa GB1449-83 | |||

| SS | Standard | Moisture | Content of Resin% | |||||

| warp knitting fabric | E WF600-1200 C -2600 | 600 | 600 | 60 | 290 | 220 | 50 | |

| E WF800-1200 C -2600 C -2600 | 800 | 800 | 60 | |||||

| bonded mat | E WFC700-1200 C -2600 | 500 | 200 | 700 | 60 | |||

| E WFC1050-1200 C -2600 | 600 | 450 | 1050 | 60 | 230 | 184 | 62 | |

| E WFC1200-1200 C -2600 C -2600 | 800 | 400 | 1200 | 60 | ||||

| stitch mat | E NC300-1200 C -2600 | 300 | 300 | 60 | ||||

| E NC380-1200 C -2600 | 380 | 380 | 60 | |||||

| E NC450-1200 C -2600 | 450 | 450 | 60 | 200 | 160 | 70 | ||

| E NC600-1200 C -2600 C -2600 | 600 | 600 | 60 | |||||

E: Glassfiber Fabric

1. Properties

Glassfiber fabric is characterized by flame-retardant, corrosion & heat resisrant, high strength and strength

and insulation, etc., It is widely in chemical industry , shipping , automobile , architecture, etc.

2. Specifications

C Glass Woven Cloth

| Specifications | Weight g/m* | Breaking Strength NN/2.5cm | Weave | Textile Density Piece/cm | ||

| Warp | Weft | Warp | Weft | |||

| CW140-90 | 140±14 | 345 | 345 | Plain | 7 | 7 |

C Glass Fiber Woven Roving

| CWR200-90 | 200±16 | 637 | 686 | Plain | 6.0 | 3.8 |

| CWR400D-90 | 350±28 | 1000 | 1000 | Plain | 4.0 | 3.5 |

| CWR400-90 | 400±32 | 1226 | 1226 | Plain | 4.0 | 3.5 |

| CWR600-100 | 600±48 | 1800 | 1700 | Plain | 3.0 | 3.4 |

| CWR800-100 | 800±64 | 2500 | 2200 | Plain | 2.0 | 2.1 |

| CWR200-90(811) | 200±16 | 750 | 750 | Plain | 6.0 | 3.8 |

| CWR300-90(811) | 300±24 | 1000 | 900 | Plain | 5.0 | 7.0 |

| CWR400-90(811) | 400±32 | 1600 | 1400 | Plain | 4.0 | 3.5 |

| CWR600-90(811) | 600±48 | 2000 | 2000 | Plain | 3.0 | 3. 2 |

E Glass Fiber Woven Roving

| EWR200-90 | 200±16 | 780 | 650 | Plain | 5. 0 | 4. 3 |

| EWR200-100 | 200+16 | 780 | 650 | Plain | 5. 0 | 4. 3 |

| EWR400-90 | 400±32 | 1480 | 1380 | Plain | 3.5 | 3. 3 |

| EWR400-100 | 400±32 | 1480 | 1380 | Plain | 3. 5 | 3. 3 |

| EWR500-100 | 500±40 | 1800 | 1700 | Plain | 3. 5 | 3. 3 |

| EWR600-100 | 600±48 | 1900 | 1800 | Plain | 3. 0 | 3. 3 |

| EWR800-100 | 800 + 64 | 2600 | 2300 | Plain | 2. 0 | 2. 0 |

| EWR300-90(811)~ | 300 + 24 | 1500 | 900 | Plain | 4. 0 | 3. 6 |

| EWR400-90 (81 1) | -400±32~ | 1 500 | 1500 | Plain | 4. 0 | 3.2 |

| EWR530-90C811) | 530±43 | 3200 | 800 | Plain | 3. 5 | 3. 2 |

Founded in 2002, Changzhou Rule Composite Material Co., Ltd, is a enterprise engaged in in manufacturing high-performance unsaturated polyester resin, gel coat, glass fiber reinforced composite materials and other related products, also professional in research, development as well as technical consulting and services of composite materials.

Rule Composite Material covers an area of 50, 000 square meters, with a modern office building, an independent R& D center and a high-standard production workshop, equipped with the leading DCS automatic control production device. We also have a strong and advanced quality control department and technical support laboratory.

RULE focuses on the production of excellent-quality and creative-design resin products, so it is trustworthy. Our sweat and wisdom witness the footprints of yesterday's struggle, passion and dream fulfill today's victory. Forging ahead to make innovation in market economy, pursuing value of "innovation, creativity, sharing" in practice, it harvests a stream of praises and honors.

Our Advantages

Why we choose Changzhou Rule Composite Material Co., Ltd?

What is resin?

Resin usually refers to products inclined to softening or melting after receiving heat. When softening, it shows a trend toward flowing under the influence of external forces. Under normal temperature, it is in solid, semi-solid state, and sometimes liquid organic polymer. Broadly speaking, any macromolecule compound that can be used as a raw material for plastic processing can be called resin.

What can resins do for you?

Resin products are widely used in sectors like railways, automobiles, wind power, shipbuilding, cooling towers, pipelines, coatings, electrical appliances, artificial stone, handicrafts, lighting tiles, sanitary ware, anti-corrosion engineering and so on. Rule has been granted certification of ISO9001: 2008 Quality Management System and ISO14001: 2004 Environmental Management System, and some products have won recognition of China Classification Society(CCS) and Food-Level Licenses of the Provincial Department of Health.

We are the professional resin solution provider.

With decades of experience in the R& D of resins, we can fully understand customers' needs and aspirations in the cooperation process and have presented countless solutions. Over the years, we work hard to optimize our products and make them attractive to end users.

This product is packed in pallets, every single roll is in a shrinkage polybag, 3-4 layers for each carton, or 48-64 rolls/each carton.

The product should be stored in the dry and open environment to prevent wetting out and also should be packed completely.

The best storage temperature is 5-35°C, moisture degree is 35-65%, this product is better to be used up in 12 months.

Maximum two layers of pallets is allowed vertically stacked if the storage space limited.