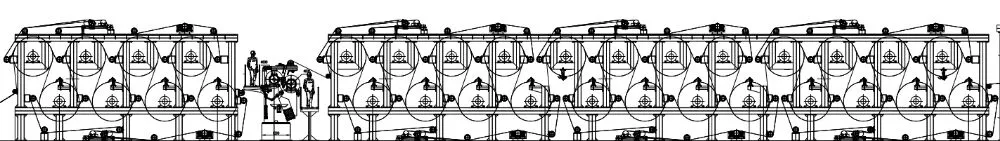

- Overview

- Product Description

- Product Parameters

- Our Advantages

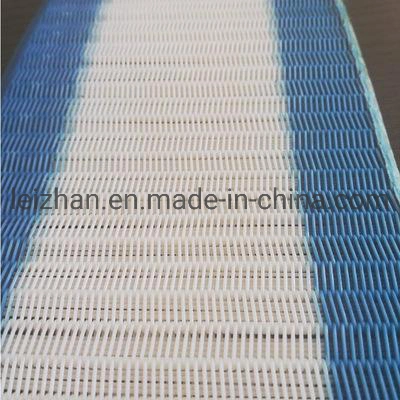

- Detailed Photos

- Packaging & Shipping

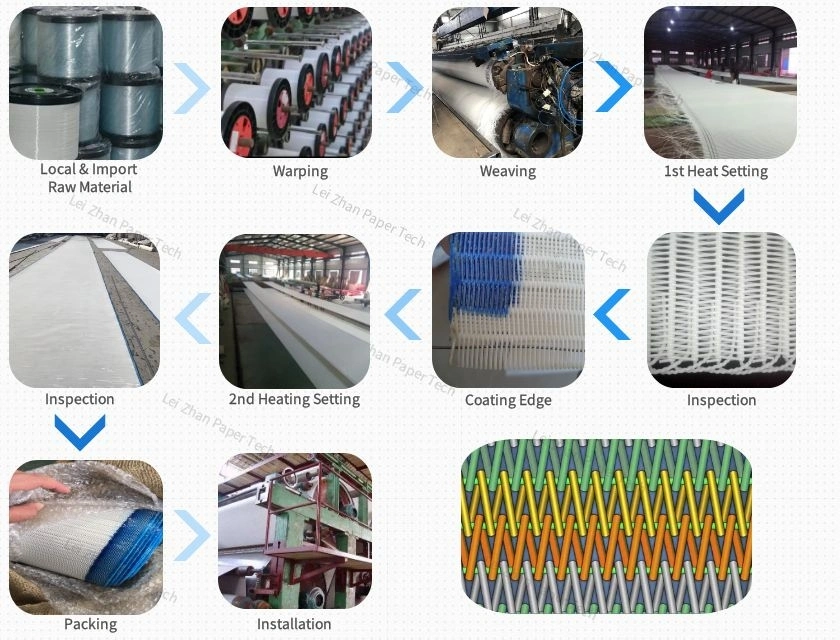

- Production Process

- Company Profile

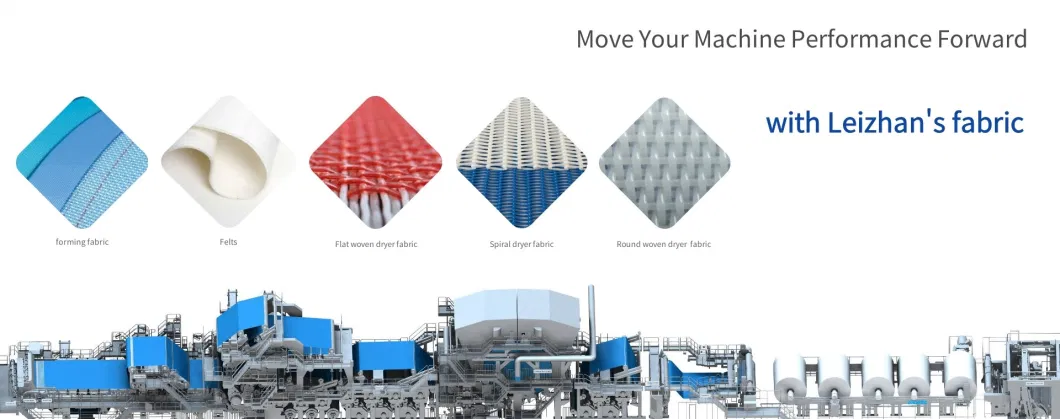

- Related Products

Basic Info.

Product Description

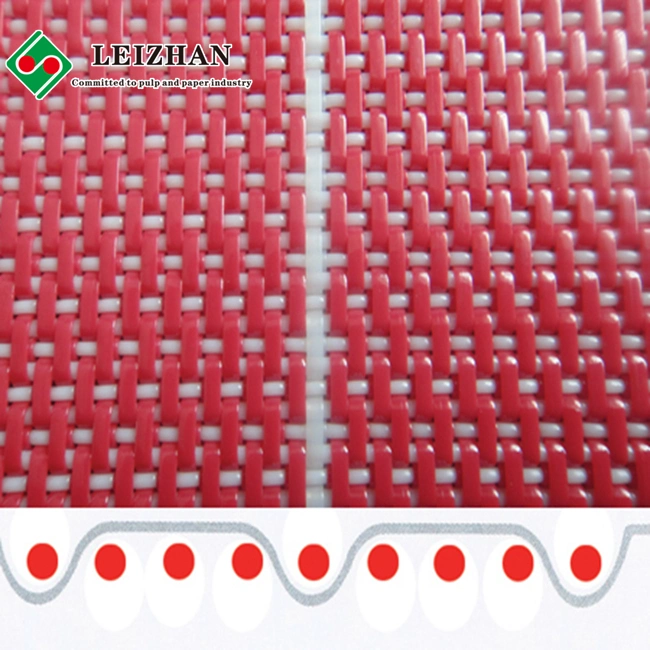

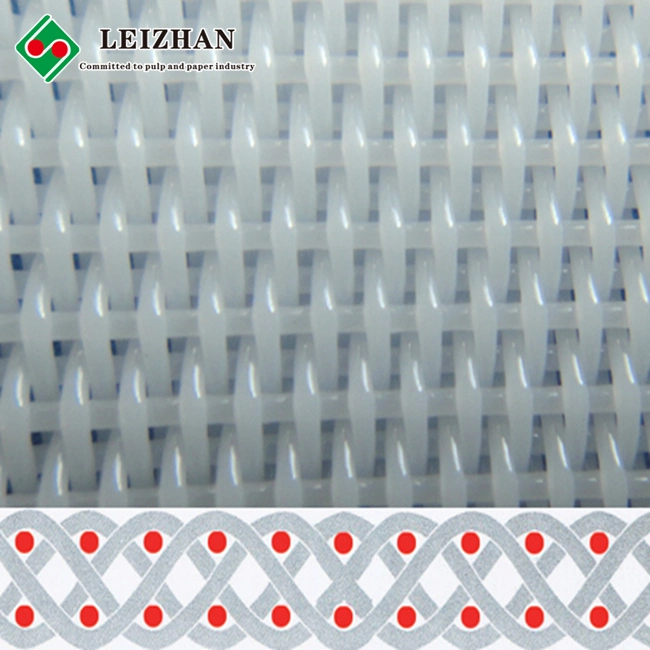

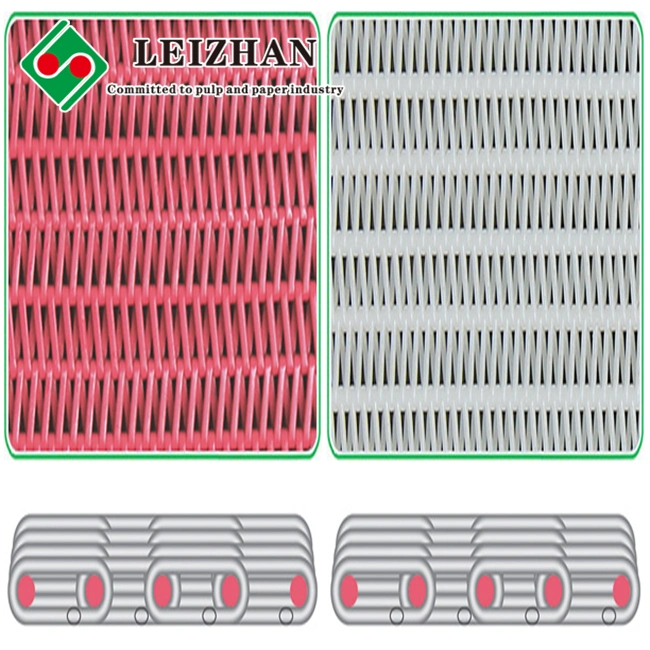

Polyester spiral dryer screen is made of polyester monofilament wound into the spiral loop, and the spiral loops are connected together with weft seams to form a spiral mesh. The spiral mesh has a smooth surface, good air permeability, high temperature resistance, and with own interface. It is widely used in the dryer section of paper machine, the production of composite fabrics, the drying and conveying of food and medicine. The spiral dryer screen effectively guarantees the continuous production of modern industrial equipment and greatly improves production efficiency.

| Polyester Spiral Dryer Screen | ||||||||

| Type | Spiral loop width (mm) | Filament diameter mm | Tensile strength N/cm | Weight Kg/m2 | Thickness mm | Air permeability M3/m2h | CFM 127/pa | |

| Spiral ring monofilament (mm) | Connection wire (mm) | |||||||

| Small Loop | 5-5.2 | 0.50 | 0.80 | 1800 | 1.00 | 2.10 | 15000 | 937 |

| Medium Loop | 8 | 0.68 | 0.90 | 2000 | 1.31 | 2.45 | 18000 | 1125 |

| 7.15 | 0.68 | 0.90 | 2000 | 1.40 | 2.45 | 16000 | 1000 | |

| 7.5 | 0.7 | 0.90 | 2200 | 1.45 | 2.60 | 16500 | 1031 | |

| 7.2 | 0.7 | 1.00 | 2200 | 1.50 | 2.45 | 16800 | 1050 | |

| Large Loop | 8 | 0.90 | 0.90 | 2300 | 1.80 | 3.03 | 19000 | 1188 |

| 10 | 0.90 | 1.10 | 2300 | 1.65 | 3.15 | 20000 | 1250 | |

| 9.15 | 1.00 | 1.00 | 2000 | 2.0 | 3.35 | 17000 | 1060 | |

| 12 | 1.20 | 1.30 | 2600 | 2.35 | 4.30 | 22000 | 1375 | |

| Small Loop Red Color | 5 | 0.62/0.30 [flat wires] | 0.80 | 1600 | 0.90 | 1.90 | 13000 | 820 |

| Large Loop Red Color | 8 | 0.90/0.60 [flat wires] | 0.90 | 1800 | 1.60 | 2.80 | 17000 | 1060 |

| HTR-01 [Heat-resisting] | 6.48 | 0.90 | 0.90 | 2000 | 1.90 | 3.30 | 14000 | 875 |

| HTR-02 [Heat-resisting] | 8.30 | 0.90 | 0.90 | 2000 | 1.74 | 3.50 | 19000 | 1188 |

1.Has the acid and alkali resistance, wear resistance, high temperature resistant, long service life

2.With smooth surface, the tensile strength, permeability is good.3. According to user requirements in filling in the grid round wire (2 to 5) (a) or black flat silk, adjust at porosity, meet the process requirements.

4.Carbon fiber through internal fill to achieve antistatic effect, with high temperature resistance, wear resistance, etc

5.Size length can be cut, and thus solve the problem of the influence because of the size is not accurate to use.

6.Install easy to use, interface without imprint

We are a China industrial felt and fabric manufacturer located at Jiangsu province,Xuzhou city. With advantage technology and excellent produce equipment,we provide one-stop service from consultation,process design and optimization , manufacture ,installation , commissioning and personnel training and so on.At the meantime,we can custom design according to customers' requirements. Through our professional analysis, we can reduce customers' costs, enhance their competitiveness, and provide customers with one-stop industrial fabric solutions.

We are a China industrial felt and fabric manufacturer located at Jiangsu province,Xuzhou city. With advantage technology and excellent produce equipment,we provide one-stop service from consultation,process design and optimization , manufacture ,installation , commissioning and personnel training and so on.At the meantime,we can custom design according to customers' requirements. Through our professional analysis, we can reduce customers' costs, enhance their competitiveness, and provide customers with one-stop industrial fabric solutions. Leizhan corporate spirit : "Unity, innovation, pragmatism, and truth-seeking".

Since the establishment of Leizhan, we have insisted on taking customer needs as our core, thinking about what customers think, worrying about what customers need, and striving to achieve customer satisfaction. We insist on growing and succeeding together with customers, and have established long-term stable and successful cooperative relations with customers in 35 countries.

We are united. In today's globalization, we unite with our customers, develop together, and make customers more successful.