Basic Info.

Packaging & Delivery

Product Description

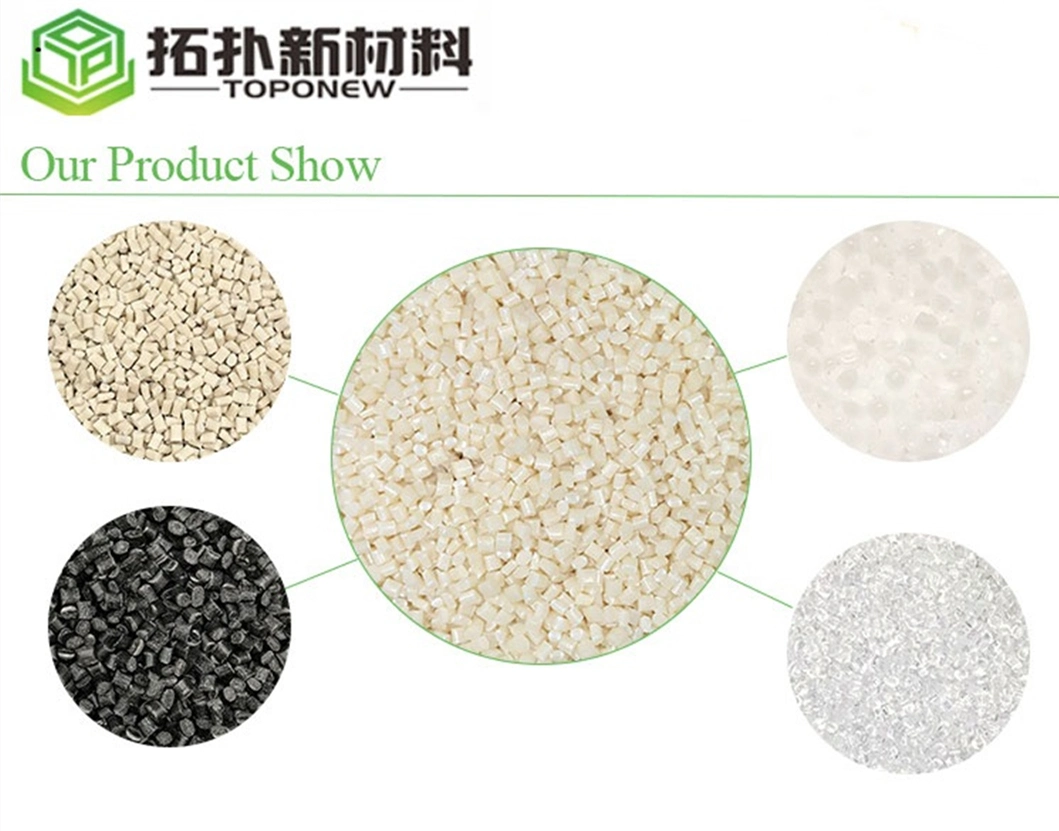

PP glass fiber reinforced GF25% high rigidity, high strength, and low shrinkage reinforced PP modified plastics

Have higher transparency, lower gloss, and lower rigidity

Have a stronger impact strength

Have good surface stiffness and scratch resistance

| PP K7760 |

| Properties | Test Method | Test Condition | Units | Typical Values |

| Physical | ||||

| Melt Flow Rate | ISO1133 | 230ºC, 2.16Kg | g/10min | 58±2 |

| Specific Gravity | ISO1183 | 23ºC | g/cm3 | -- |

| Ash | ISO3451 | 800ºC,30min | % | -- |

| Mechanical | ||||

| Tensile Strength | ISO527 | 50mm/min | MPa | 24 |

| Elongation at Break | ISO527 | 50mm/min | % | 6 |

| Flexural Strength | ISO178 | 2mm/min | MPa | -- |

| Flexural Modulus | ISO178 | 2mm/min | MPa | -- |

| Impact Strength, IZOD non-notched | ISO179 | 23ºC | KJ/m2 | NB |

| -30ºC | KJ/m2 | - | ||

| Impact Strength, IZOD notched | ISO179 | 23ºC | KJ/m2 | - |

| -30ºC | KJ/m2 | - | ||

| Thermal | ||||

| Heat Deflection Temp. | ISO75 | 0.45MPa | ºC | 95 |

| 1.8MPa | ºC | - | ||

| (Melting Point) | DSC | ºC | ||

| Others | ||||

| Hardness | ISO2039 | - | N/mm2 | |

| Mold Shrinkage | - | 23ºC | ||

| Flammability | TL1010 | - | mm/min | |

1. The data in the table is the test data of the product performance, but the value cannot be used as the guarantee value of the performance in the specific use, only for the user's preference.

2. The data on the flammability level in the table is not intended to reflect the degree of danger of the material under actual fire conditions.

Polypropylene (PP) products use grade :

1). Film Grade

- Biaxial Orientation Stretching Polypropylene (BOPP): mainly used in the production of high-stiffness, high transparency packaging film. It is also widely used in the production of printing and laminated film, Matt film, pearlized film, synthetic paper, cigarette film, etc

- Casting Polypropylene(CPP): It is also widely used as the packing for clothing, stationery, food, medicine, cosmetics, textiles, etc.

2). Injection Molding Grade

- PP Impact Copolymer: widely used in the production of industrial products, such as dashboard, auto interior decorations, auto bumpers, interior and exterior parts of washing machine, accumulator containers, and tanks. can also be used to make household articles, such as bottle caps, cookware, furniture, toys, toolkits, travel cases, bags, and various packaging containers.

- PP Random Copolymer: widely used in the production of medical appliances with high transparency, such as medical syringes, medical infusion bottles, medical centrifuge tubes, and sample tubes. It is used in the production of food containers, stationery, packaging materials, and houseware.

- PP Homopolymer: widely used in the production of small electrical household appliances, such as electric kettles, electric utensils, electric irons, air heaters, electric hair dryers, electric toasters, and electric hand dryers.

3). Pipe Grade

PP Pipe Grade is mainly used in the production of pipes used in building water supply systems, heating systems, and chemical piping systems. Finished Products by lightweight, corrosion resistance, long service life, thermal retardation, and recyclable processing scrap.

4). Fiber Grade

PP Fiber Grade is widely used in the production of bulked continuous filament (BCF), fine and superfine staple fiber, cigarette filter tow, and superfine non-woven fabric in high-speed and ultrahigh-speed spinning and spun-bonded non-woven fabric production.

5). Yarn Grade

PP Yarn Grade is widely used in the production of woven bags, colored stripe cloth for sunlight shading or covering use, carpet backing (base fabric), container bags, tarpaulin, and ropes.

6). Coating Grade

PP Coating Grade is mainly used for coating woven bags, tarpaulin, colored stripe cloth, and pipes.

7). Powder Grade

PP powder grade is mainly used to produce general-purpose products such as ropes, woven bags, packaging tapes, toys, daily necessities, and non-woven fabric.

Are you a trading company or manufacturer?

We are a manufacturer.

About Sample?

A 5 KG Free Sample can be offered per your request.

About Material Color?

We can make the material to your appointed color according to Pantone/RAL#.

How does your factory control the quality?

Quality is the Priority, we always pay great importance to quality from beginning to end, we have professional QC for item quality from spare parts to finished goods.

How many days for mass production?

20 days after all artwork and 30% deposit are confirmed.

How can I get the samples? Is the sample free?

7-10 days to send free samples by DHL, TNT, and UPS.