- Overview

- Product Description

Basic Info.

Model NO.

Full set type

Material Type

Nylon

Elongation at Break

400%

Tensile Strength

55MPa

Maximum Use Temperature

204 Degrees Centigrade

Colour

Yellow

Thickness

65um

Transport Package

Pallet

Specification

65um thickness

Trademark

UTEK

Origin

China

HS Code

392062

Production Capacity

1000ton/Year

Product Description

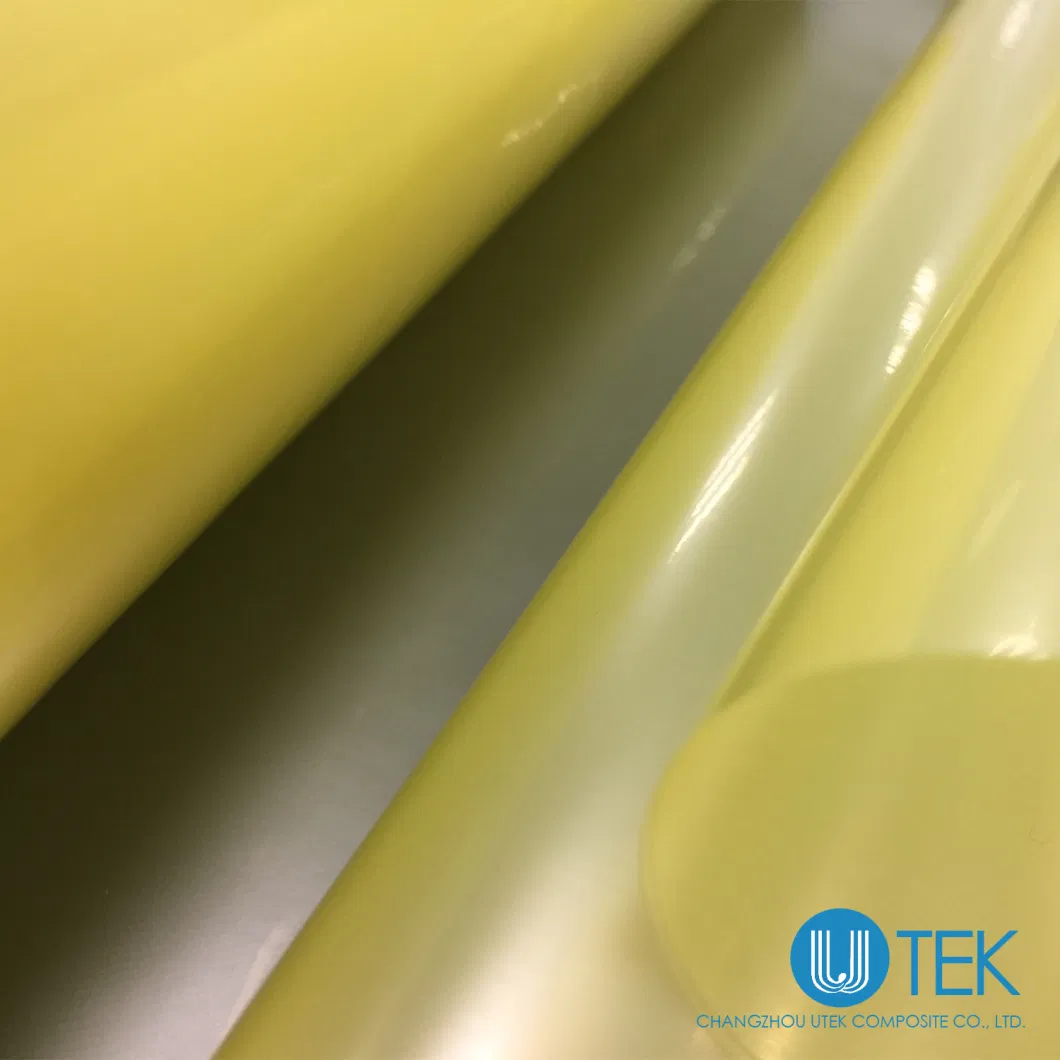

Vacuum Bagging Film

Regular type: Nylon Vacuum bagging film, Yellow color, 65um thickness, 6m width, 120ºC temperature resistance.

(Production can be customized as customer requirements: temperature resistance 90ºC-260ºC, width 0.1m-16m, thickness 50um-75um. )

Applications:

Wind energy: blades, nacelle covers, hubcap, etc

Shipbuilding industry: hull, deck, bulkhead, superstructure, etc

Transportation industry: cars, trains, high-speed trains, subway parts, etc

Sports industry: surfboard, snowboard, sleds, kayaking, canoe, model airplane, bicycle, fishing tackle, etc

Regular type: Nylon Vacuum bagging film, Yellow color, 65um thickness, 6m width, 120ºC temperature resistance.

(Production can be customized as customer requirements: temperature resistance 90ºC-260ºC, width 0.1m-16m, thickness 50um-75um. )

Applications:

Wind energy: blades, nacelle covers, hubcap, etc

Shipbuilding industry: hull, deck, bulkhead, superstructure, etc

Transportation industry: cars, trains, high-speed trains, subway parts, etc

Sports industry: surfboard, snowboard, sleds, kayaking, canoe, model airplane, bicycle, fishing tackle, etc

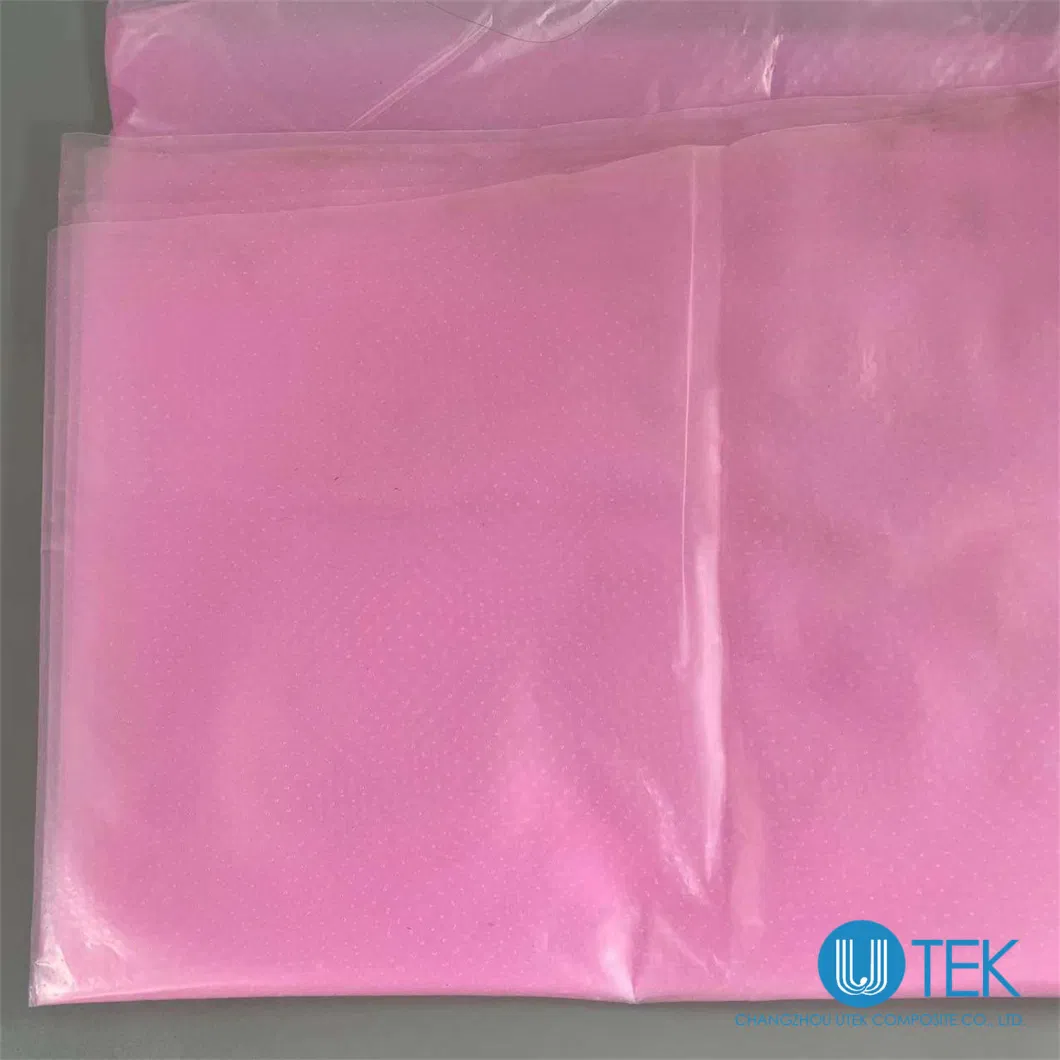

Release Film

Release films allow for the removal from the composite part of other process materials such as breather fabric and flow media. A wide variety of available perforation patterns, including pin-prick, hot needle and punched, allow manufacturers to tightly control resin bleed in various composite manufacturing processes.

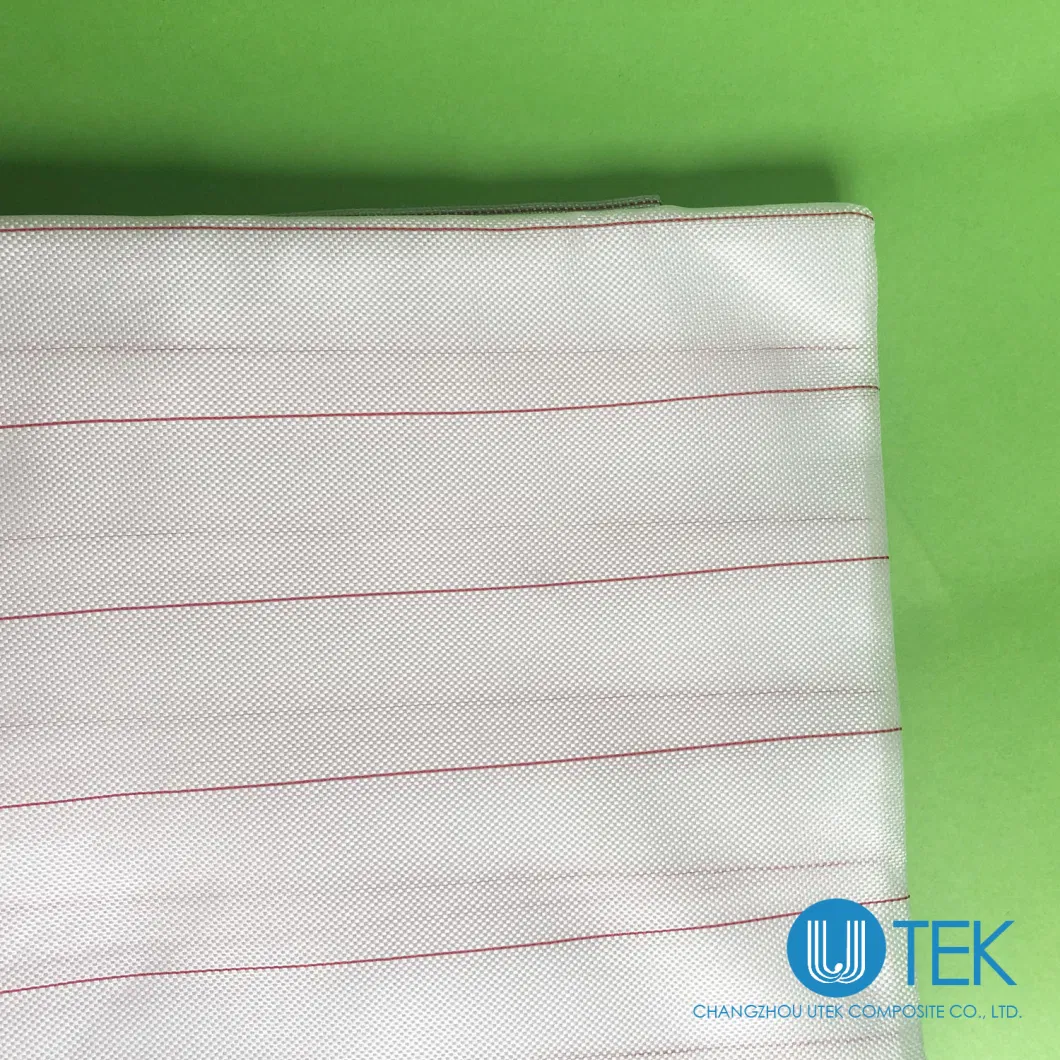

Peel Ply

Peel-ply is a tightly woven disposable polyester or nylon cloth, that used in a number of composites manufacturing processes including conventional wet-layup, resin infusion, vacuum bagging and some prepreg applications.

Peel-ply is a tightly woven disposable polyester or nylon cloth, that used in a number of composites manufacturing processes including conventional wet-layup, resin infusion, vacuum bagging and some prepreg applications.

- Temperature resistance 150~203°C

- No release agent coating on the surface, will not pollute the product;

- It has good mold release and obvious marking line,can prevent leakage and residue;

- Fabric texture is formed on the surface of the product after stripping, improve the shear force of structural bonding, make easy for secondary bonding and sanding

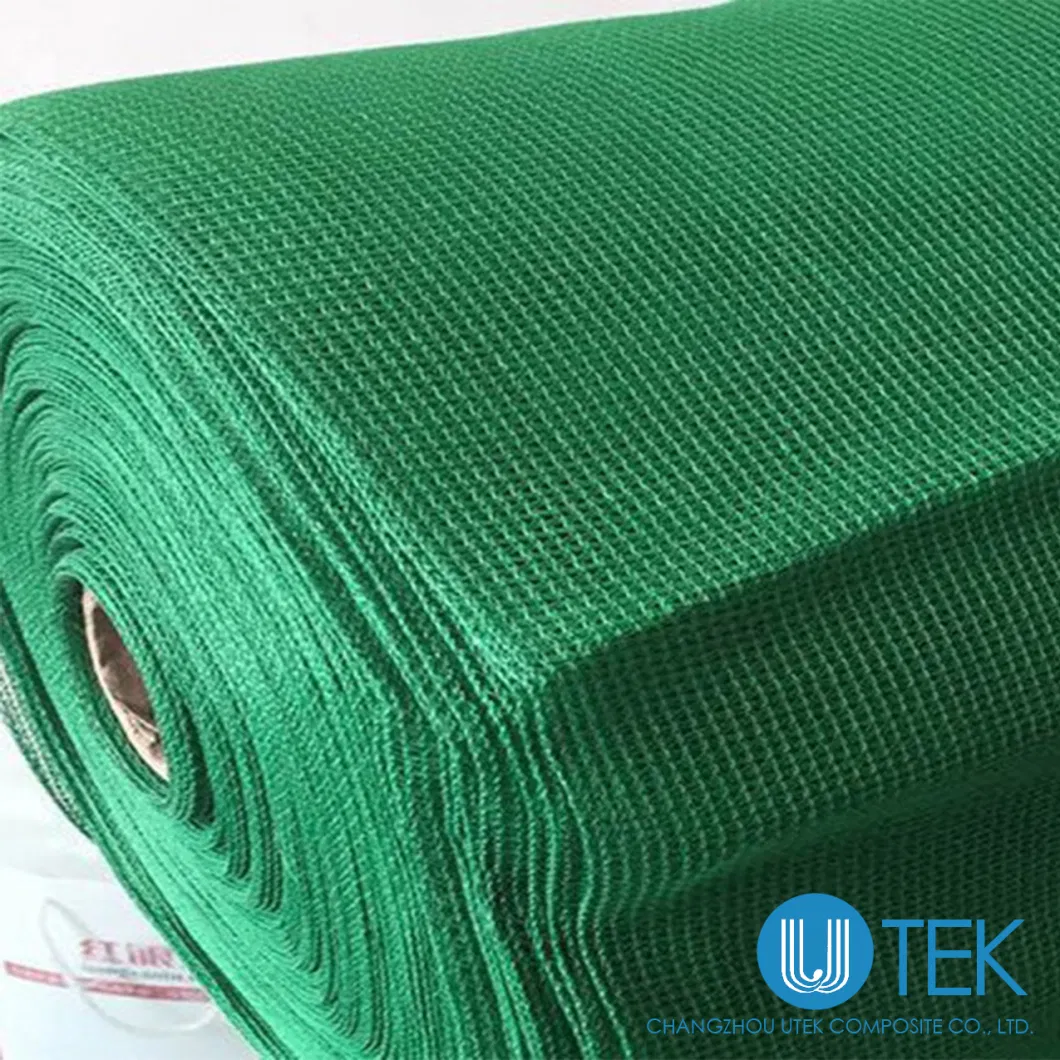

Flow Mesh

It is a flow media designed to efficiently distribute resin with little waste due to its low profile and tight construction.

Green flow is compatible with polyester, vinylester, and epoxy resins.

Sold in full rolls. A full roll is 100 meters long.

This material is used for vacuum infusion and is placed on top of peel ply.

The material is used to allow a quick flow for resin to travel across the part while under vacuum.

Very easy to use and works great.

It is a flow media designed to efficiently distribute resin with little waste due to its low profile and tight construction.

Green flow is compatible with polyester, vinylester, and epoxy resins.

Sold in full rolls. A full roll is 100 meters long.

This material is used for vacuum infusion and is placed on top of peel ply.

The material is used to allow a quick flow for resin to travel across the part while under vacuum.

Very easy to use and works great.

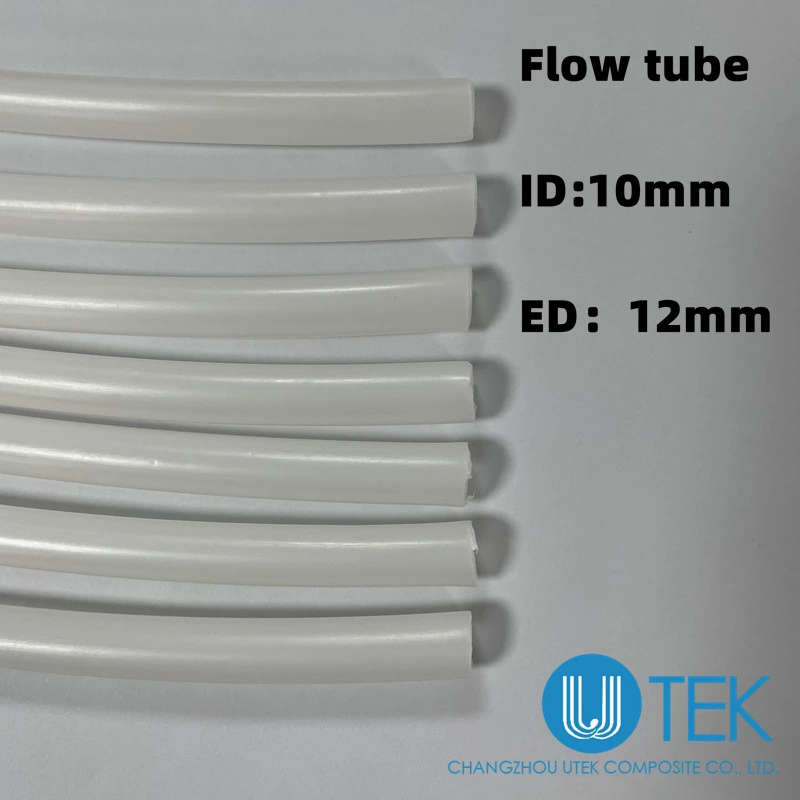

Resin Tube

Spiral Tubing is a resin infusion standard and is ideally suited for in-bag vacuum line extenders or resin feed lines.

This tubing is often used in vacuum infusion to allow vacuum pressure to be easily dispersed around a part.

Inner diameter (ID) is 8~13mm; outer diameter (OD) is 10~16mm

Maximum Temperature range: 176°F(80ºC)

To ensure resin flow is not impeded, we recommend wrapping tubing in nylon or polyester peel ply.

Spiral Tubing is a resin infusion standard and is ideally suited for in-bag vacuum line extenders or resin feed lines.

This tubing is often used in vacuum infusion to allow vacuum pressure to be easily dispersed around a part.

Inner diameter (ID) is 8~13mm; outer diameter (OD) is 10~16mm

Maximum Temperature range: 176°F(80ºC)

To ensure resin flow is not impeded, we recommend wrapping tubing in nylon or polyester peel ply.

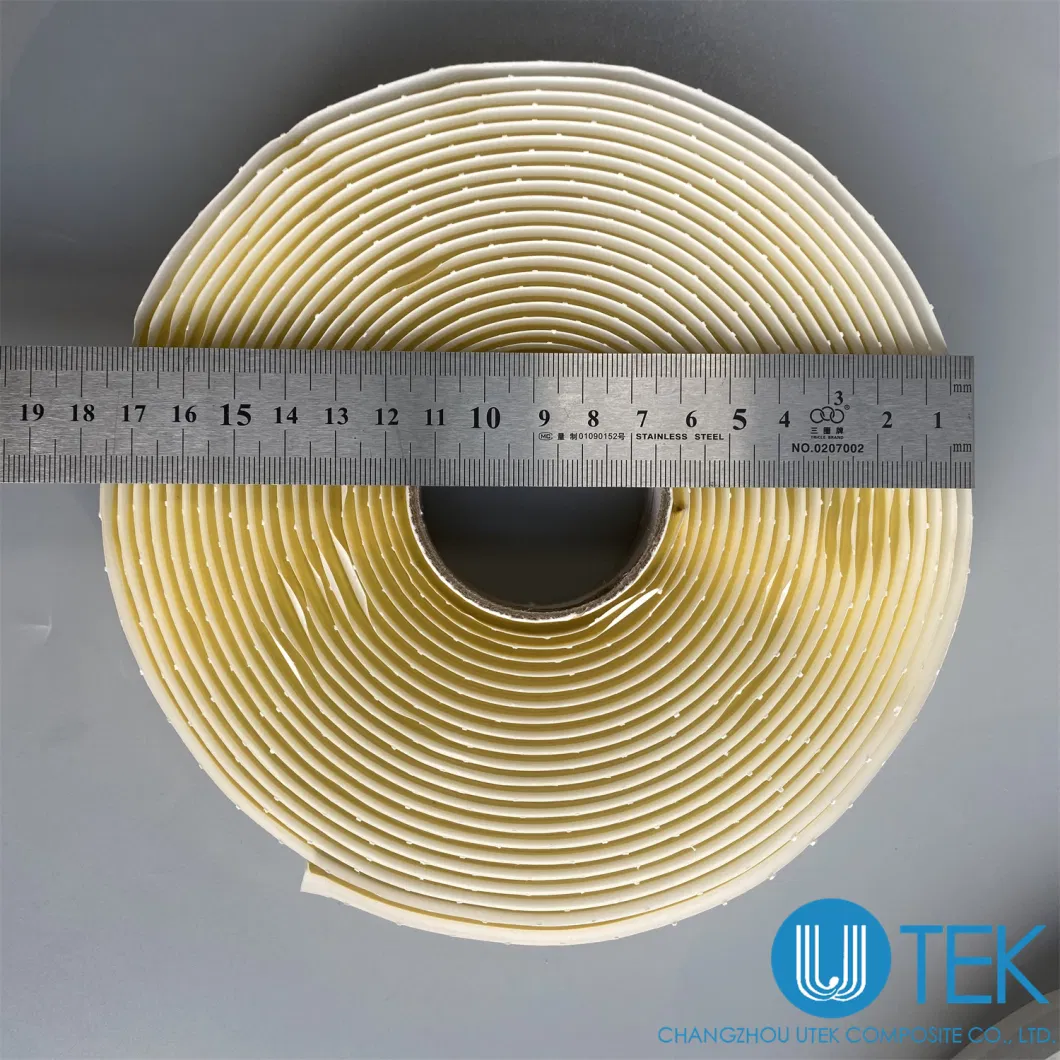

Sealant Tape

The sealant tape has good temperature resistance and it is easy to use.It is designed for the composites industry; it can be used as a vacuum seal. It has excellent sealing performance in the high temperature and high pressure during the curing the resin, ensuring that the vacuum bag is vacuumed and not easily leaked.

Temperature resistance: 100C, 120C, 150C, 200C, 230C

The sealant tape has good temperature resistance and it is easy to use.It is designed for the composites industry; it can be used as a vacuum seal. It has excellent sealing performance in the high temperature and high pressure during the curing the resin, ensuring that the vacuum bag is vacuumed and not easily leaked.

Temperature resistance: 100C, 120C, 150C, 200C, 230C

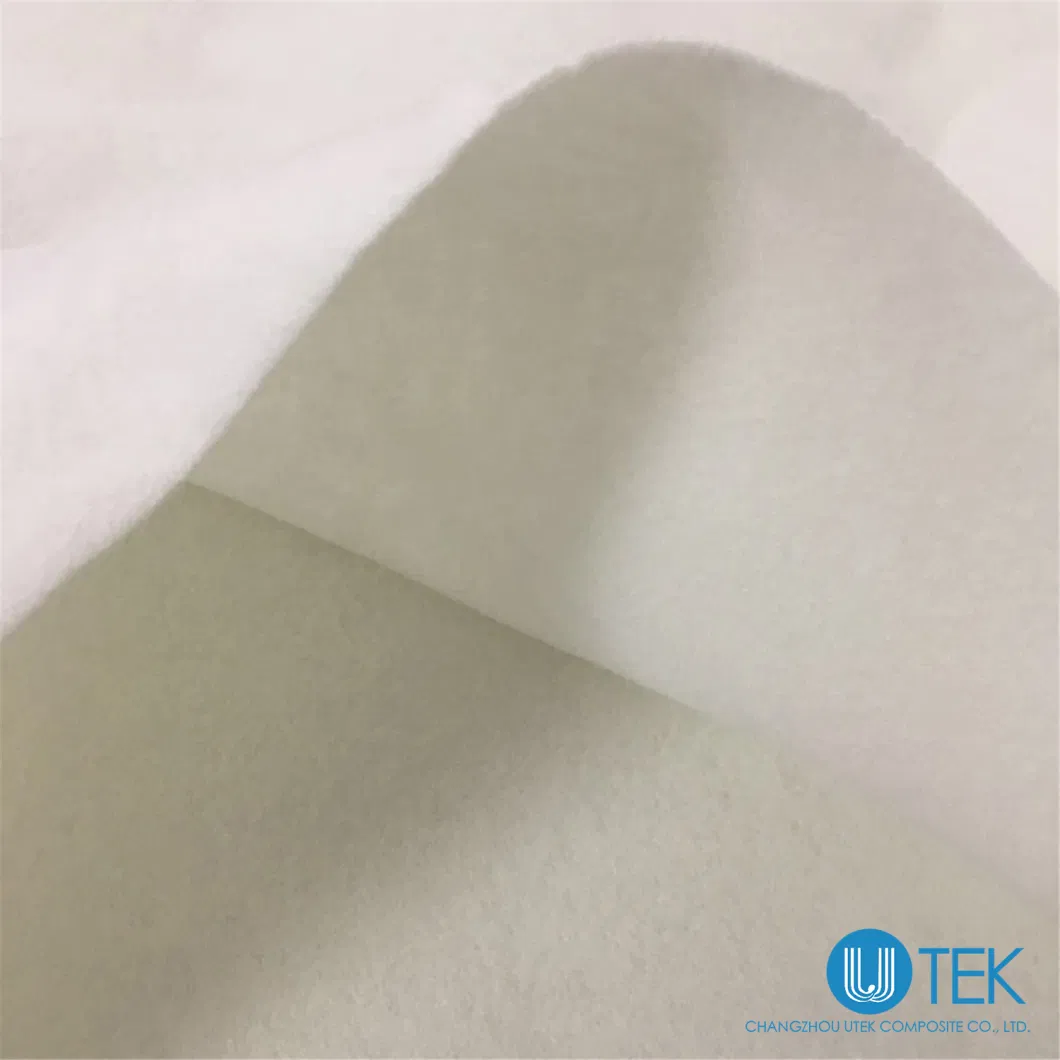

Breather Cloth

Breather cloth is suitable for a variety of vacuum breather products, using nylon fiber processing. After strict rinsing and heat setting, the surface is clean without contaminants.It has excellent air permeability and fit, being stable under high temperature conditions, and has good ductility.It can be lined in a variety of sharp-angled arc products, special structure provides isotropic air permeability.It can be used in the temperature range of 200-232 ° C, suitable for wet and prepreg process; can be effectively adsorb excess resin to improve product performance.

Breather cloth is suitable for a variety of vacuum breather products, using nylon fiber processing. After strict rinsing and heat setting, the surface is clean without contaminants.It has excellent air permeability and fit, being stable under high temperature conditions, and has good ductility.It can be lined in a variety of sharp-angled arc products, special structure provides isotropic air permeability.It can be used in the temperature range of 200-232 ° C, suitable for wet and prepreg process; can be effectively adsorb excess resin to improve product performance.

Give us a chance, and we' ll return you with satisfaction.