Basic Info.

Model NO.

TSZD-40

Application

Chips

Customized

Customized

Material

Food Grade Stainless Steel

Basket

Circular

Heating Method

Electric Heating

Power

113kw

Heating Time

25-45minutes

Oil Capacity

550L

Applications

Chips,Snack Foods

Transport Package

According to Customer Requirements

Specification

4000*1680*1900mm

Trademark

AMBITIOUS

Origin

China

HS Code

843860000

Production Capacity

200pieces/Year

Product Description

Electric Teflon Belt Continous Frying Machine Conveyor Tempura Fryer

1. -Machine Introduction

Automatic Continuous Frying Machine is made of food grade stainless steel, consists of lifting system, conveying system, gas heating system, blowdown system, oil circulation system, smoke exhaust system and electric control system.

Features&Advantages of the continuous fryer:

1)Frying machine is suitable for continuous food production with high output.

2)The products are layered between upper and lower mesh belt so as to avoid

floating when they are fried in frying oil.

3)The transmission system of the frying machine is designed as frequency

stepless speed regulation, this can help the operator to control the frying

time freely.

4)The equipment is equipped with automatic lifting system, help the mesh belt

to be cleaned more easily.

5)Automatic scraping system can continuously take away the oil residue produced

in the frying process from the bottom, this can keep the frying oil clean and

extend the service life of frying oil.

6)Multi group temperature control system, can save more electricity consumption.

7)Unique temperature control panel, make operating easy, simple and safe.

The conveyor belt can be customized according to the size of the nuts.

We provide the following frying equipment:

Potato chips frying machine;

French fries frying machine;

Walnut frying machine;

Fish frying machine;

Tofu frying machine;

Beans frying machine;

Chicken nuggets frying machine;

Chicken feet frying machine;

Peanut frying machine;

Porkskin frying machine;

Onion rings frying machine;

Samosa frying machine;

Eggplant frying machine;

Namkeen frying machine.

Features:

1. The frying basket will automatically turn out of the pan and return to the pan, and the oil can be drained automatically during the pan, and the draining time can be adjusted.

2. The heating method adopts stainless steel electric heating tube.

3. Choose DN50 large-diameter ball valve, and the cone-shaped bottom of the pot discharges completely and is not easy to be blocked and is easy to clean.

4. The discharge port of the frying basket is equipped with a material receiving device to ensure that the material is completely poured out.

5. Automatic temperature control electrical appliances are equipped with emergency stop, short circuit, overload, and grounding functions. The pot body fiber cotton keeps warm to prevent scalding.

2. -Technical Data

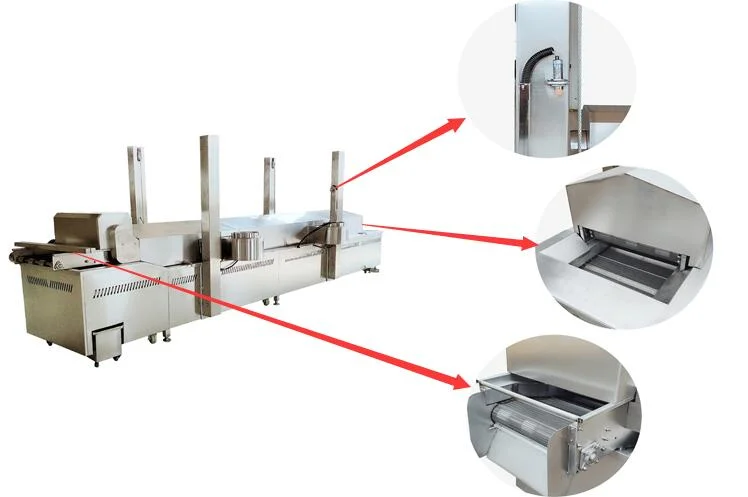

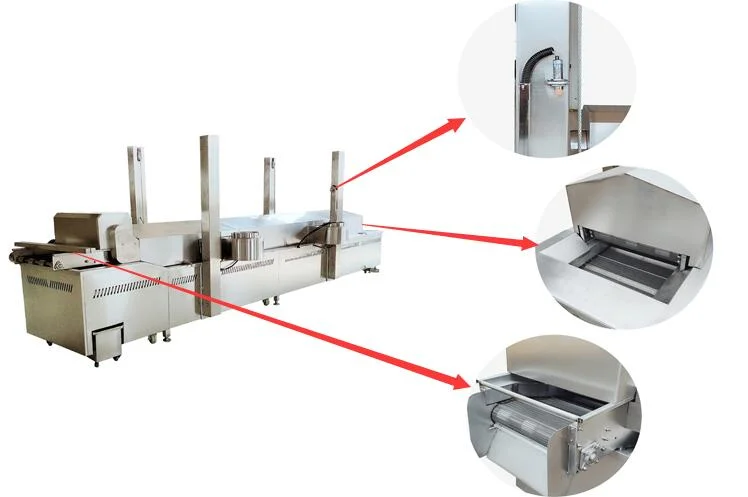

3. -Details

4. -Suitable For Products

In addition to deep-frying farsan, groundnuts,fish ball, tofu, onion, plantain chips, pork skin, port, prawn cracker, this frying machine can also be used for frying nuts such as almonds, sunflower seeds, broad beans, green beans, chicken, fish, chips,

and other snack foods, etc.

5. -Using Scene

6. -Applications

The equipment is suitable for canteens, central kitchens, fast food restaurants, meat food factories, snack food factories.

7. -Company Profile

Zhucheng Tianshun Machinery Co., Ltd. is a modern food machinery manufacturer integrating R&D, manufacturing, marketing and after-sales.

Main products including food processing machinery, including:

Vegetable/fruits washing machines;

Vegetable peeling machines;

Frying machines;

Coating&blender equipment;

Flavouring machines;

Blancher;

Hot/cool air drying machines;

Vacuum packaging machines;

Vegetable/fruits cutter;

Pasteurizer equipment;

Vacuum fryer;

Freeze dryer;

Liquid nitrogen freezer;

Complete production lines,potato chips/french fries production line,plantain chips line,vegetable/fruits processing line,etc.

They are mainly used for processing vegetable, fruits, pickled foods, chicken, meat, seafood, and so on. All of the products could be customized produce in individual or a complete line.

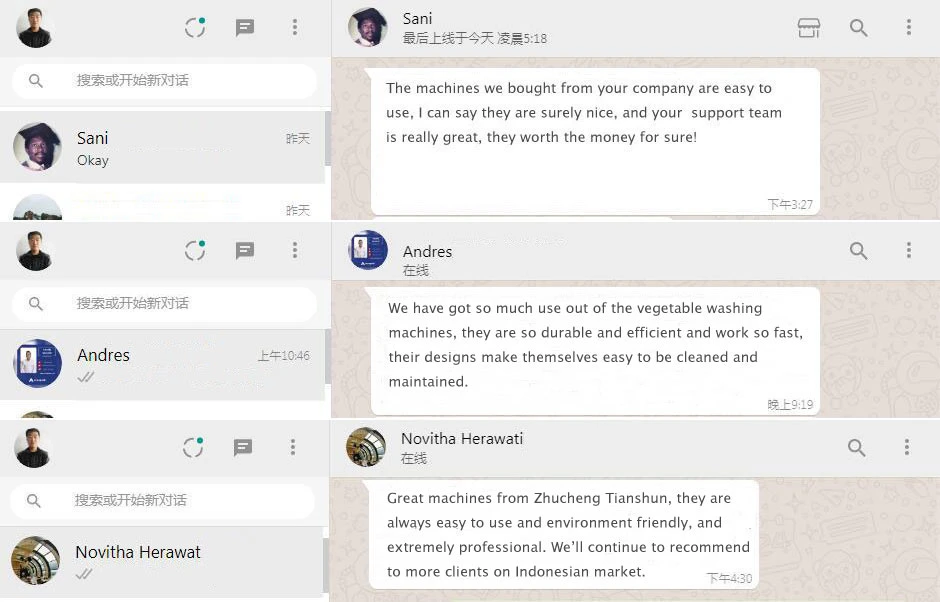

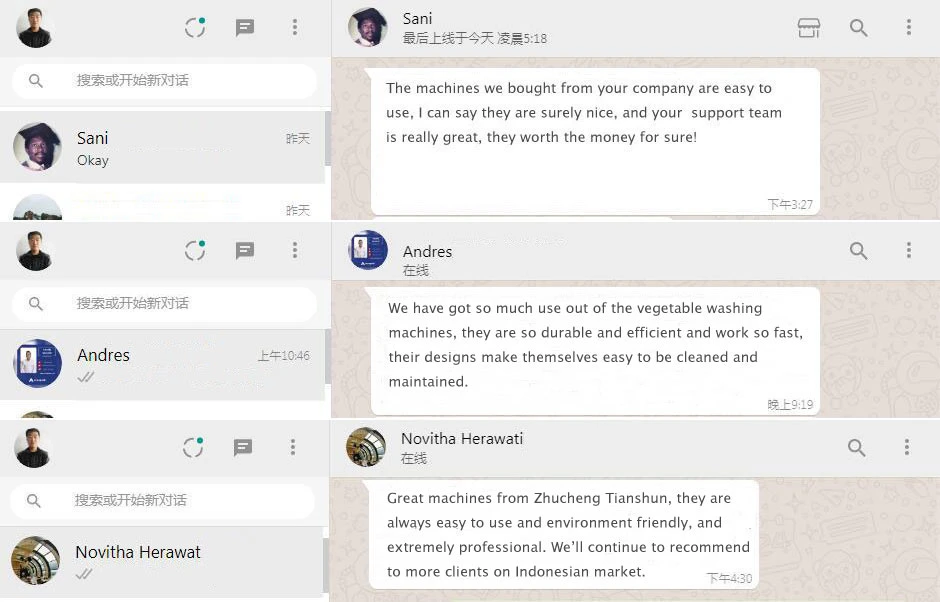

8. -Our Clients

9. -Packing And Shipment

10. -FAQ

Q1.Could we visit your factory to check the machine carefully and closely?

A:Welcome to our facotry,will provide machines testing service,face-face discussing,turnkey project design solution.

Q2.How long is your machine's guarantee time?

A:1 year without normal wear parts,machine itself life guaranteed.

Q3.If we have very special request for the complete production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q4.If we show you our layout of factory,can you help to design the whole process line?

A:Layout design service provided after received customer's factory layout size.

Q5.If we have samples of new products,can you help to analysis and design the machine?

A:Yes,our technical department can help to analysis,design and test the new products based on the specific requirements you provided.

1. -Machine Introduction

Automatic Continuous Frying Machine is made of food grade stainless steel, consists of lifting system, conveying system, gas heating system, blowdown system, oil circulation system, smoke exhaust system and electric control system.

Features&Advantages of the continuous fryer:

1)Frying machine is suitable for continuous food production with high output.

2)The products are layered between upper and lower mesh belt so as to avoid

floating when they are fried in frying oil.

3)The transmission system of the frying machine is designed as frequency

stepless speed regulation, this can help the operator to control the frying

time freely.

4)The equipment is equipped with automatic lifting system, help the mesh belt

to be cleaned more easily.

5)Automatic scraping system can continuously take away the oil residue produced

in the frying process from the bottom, this can keep the frying oil clean and

extend the service life of frying oil.

6)Multi group temperature control system, can save more electricity consumption.

7)Unique temperature control panel, make operating easy, simple and safe.

The conveyor belt can be customized according to the size of the nuts.

We provide the following frying equipment:

Potato chips frying machine;

French fries frying machine;

Walnut frying machine;

Fish frying machine;

Tofu frying machine;

Beans frying machine;

Chicken nuggets frying machine;

Chicken feet frying machine;

Peanut frying machine;

Porkskin frying machine;

Onion rings frying machine;

Samosa frying machine;

Eggplant frying machine;

Namkeen frying machine.

Features:

1. The frying basket will automatically turn out of the pan and return to the pan, and the oil can be drained automatically during the pan, and the draining time can be adjusted.

2. The heating method adopts stainless steel electric heating tube.

3. Choose DN50 large-diameter ball valve, and the cone-shaped bottom of the pot discharges completely and is not easy to be blocked and is easy to clean.

4. The discharge port of the frying basket is equipped with a material receiving device to ensure that the material is completely poured out.

5. Automatic temperature control electrical appliances are equipped with emergency stop, short circuit, overload, and grounding functions. The pot body fiber cotton keeps warm to prevent scalding.

2. -Technical Data

| Model | TSZD-40 |

| Structure | Deep Frying Oil |

| Overall size | 4000*1680*1900mm |

| Effective size | 2800*520*90mm |

| Working oil capacity | 550L |

| Voltage/frequency | 380V/50HZ |

| Total power | 103KW |

3. -Details

4. -Suitable For Products

In addition to deep-frying farsan, groundnuts,fish ball, tofu, onion, plantain chips, pork skin, port, prawn cracker, this frying machine can also be used for frying nuts such as almonds, sunflower seeds, broad beans, green beans, chicken, fish, chips,

and other snack foods, etc.

5. -Using Scene

6. -Applications

The equipment is suitable for canteens, central kitchens, fast food restaurants, meat food factories, snack food factories.

7. -Company Profile

Zhucheng Tianshun Machinery Co., Ltd. is a modern food machinery manufacturer integrating R&D, manufacturing, marketing and after-sales.

Main products including food processing machinery, including:

Vegetable/fruits washing machines;

Vegetable peeling machines;

Frying machines;

Coating&blender equipment;

Flavouring machines;

Blancher;

Hot/cool air drying machines;

Vacuum packaging machines;

Vegetable/fruits cutter;

Pasteurizer equipment;

Vacuum fryer;

Freeze dryer;

Liquid nitrogen freezer;

Complete production lines,potato chips/french fries production line,plantain chips line,vegetable/fruits processing line,etc.

They are mainly used for processing vegetable, fruits, pickled foods, chicken, meat, seafood, and so on. All of the products could be customized produce in individual or a complete line.

8. -Our Clients

9. -Packing And Shipment

10. -FAQ

Q1.Could we visit your factory to check the machine carefully and closely?

A:Welcome to our facotry,will provide machines testing service,face-face discussing,turnkey project design solution.

Q2.How long is your machine's guarantee time?

A:1 year without normal wear parts,machine itself life guaranteed.

Q3.If we have very special request for the complete production line,could you help me to do the design?

A:Experienced mechanical designer customized-design provided.

Q4.If we show you our layout of factory,can you help to design the whole process line?

A:Layout design service provided after received customer's factory layout size.

Q5.If we have samples of new products,can you help to analysis and design the machine?

A:Yes,our technical department can help to analysis,design and test the new products based on the specific requirements you provided.