- Overview

- Product Description

- Company Profile

Basic Info.

Product Description

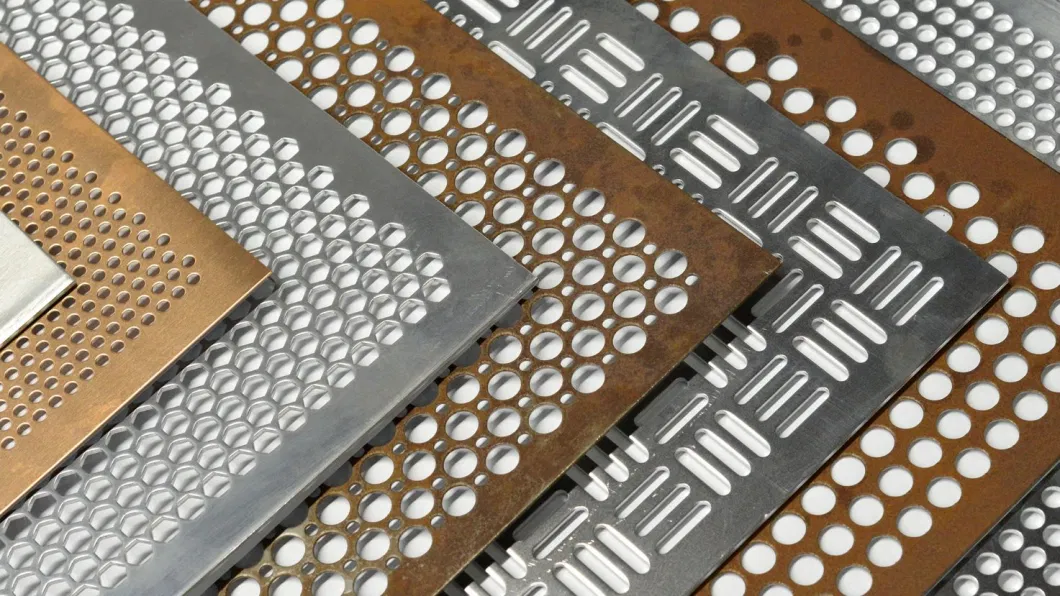

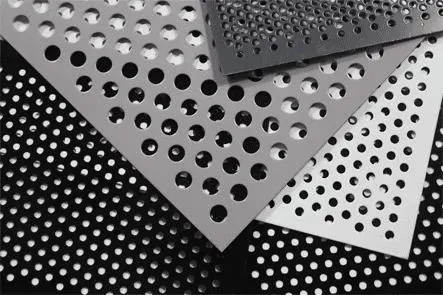

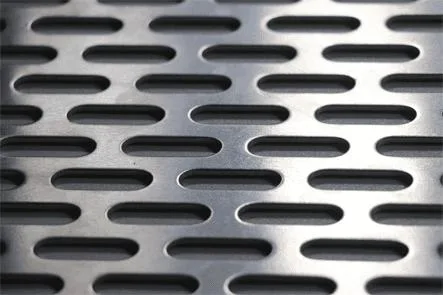

Manufacturer of custom perforated metal sheets or coils from China, a wide variety of material options include aluminum, steel, galvanized steel, stainless steel and copper. Hole types support round holes, square holes, slotted holes, hexagonal holes and some complex designs with patterns/text. Hole sizes and opening ratios can be customized upon request, and a variety of color and style finish options (powder coating, fluorocarbon coating and anodizing) are available.

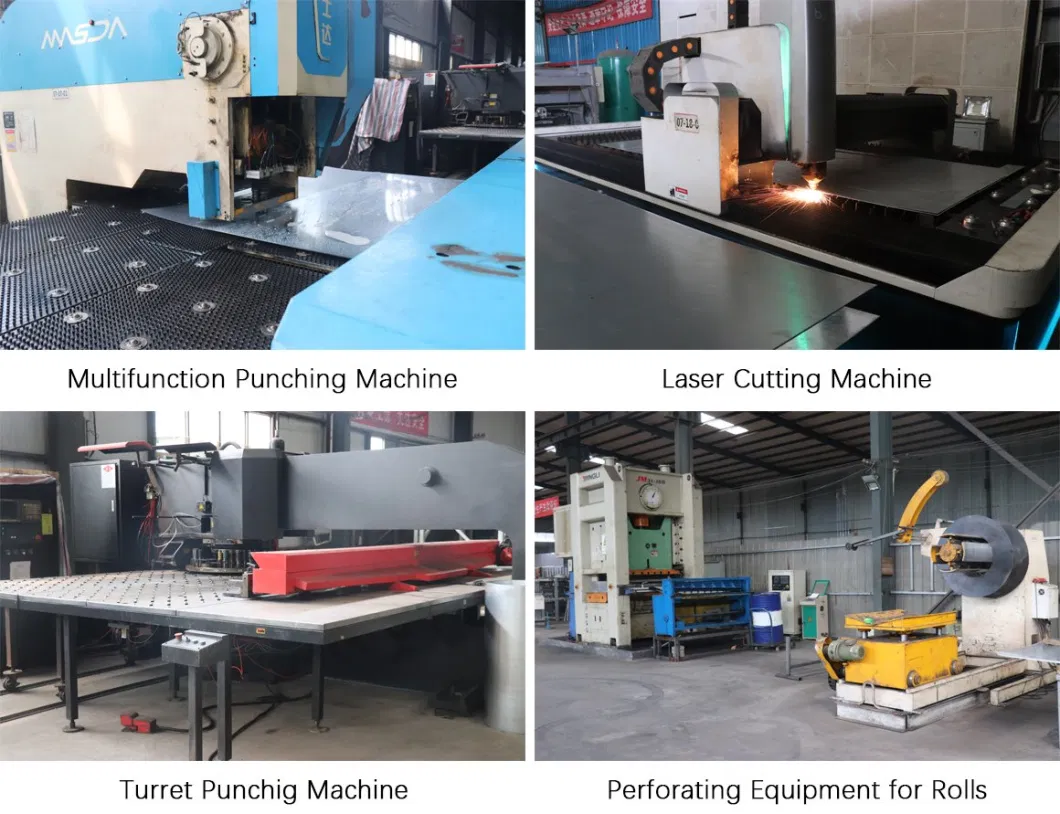

We also offer customized processing services to create different perforated metal sheets for your special needs: shearing, forming, laser cutting, bending, welding, etc. Dongfu Perforating is your one-stop perforated metal solution provider. With years of industry experience and overseas export experience, we can provide reliable and comprehensive solutions for each of our customers' projects.

With proven manufacturing processes, advanced production equipment, and professional technicians, we can customize and manufacture any type of perforated metal products to your exact requirements and deliver them on time. Whether for architectural applications, industrial applications, or the development of local businesses of any size or scope, we will invest in your success and become your most trusted partner of industrial perforated metal.

| Dongfu Perforated Metal Sheet Overview | |

| Main Materials: | Plain steel, mild steel, carbon steel, stainless steel (302, 304, 304L, 316, 316L), aluminum, copper, brass, pre-galvanized steel, hot or cold galvanized steel, etc. |

| Surface Treatment: | Electric galvanized, hot-dipped galvanized, PVC coated, powder coating, oxidation treatment, etc. |

| Width by Length: | 1000 x 2000 mm to 2000 x 6000 mm or according to customer's requirements. |

| Standard Sizes: | 1000mm × 2000mm, 1000mm × 2400mm, 1200mm × 2400mm. |

| Hole Patterns: | Round hole, square hole, slotted hole, hexagonal hole, decorative hole. |

| Hole Diameter: | 0.2 - 100 mm. |

| Margin Types: | Safe margins or no margins. |

Perforated Metal Material Options

Perforated products made from different metal materials vary in cost, performance, durability, and safety.Material Grade: Aluminum, 1050/1060/1070/3003/5005/6061, etc

Available Hole Types: Round hole, square hole, slotted hole, hexagonal hole, any decorative patterns or text

Available Finishes: Original, powder coating, fluorocarbon coating, anodizing

Thickness Range: 0.5mm - 4mm

Material Grade: Steel, Q235/Q195

Available Hole Types: Round hole, square hole, slotted hole, hexagonal hole, any pattern or text

Available Finishes: Hot-dip galvanized, 40g - 120g zinc content

Thickness Range: 0.3mm - 15mm

Material Grade: Stainless Steel, 201/304/316/316l, etc

Available Hole Types: Round hole, square hole, slotted hole, hexagonal hole, any decorative patterns or text

Available Finishes: Original, polishing

Thickness Range: 0.4mm - 6mm

Copper can also be used as a building material, and while it is not as strong and hard as steel or stainless steel, the superior appearance is visually stunning.

Perforated copper panels also serve the same purpose, whether for architectural structures, interior or exterior design, and furniture to create an atmosphere of noble appearance. Coupled with different styles of textured designs, perforated copper panels are becoming increasingly popular with modern architects and designers.

Perfect for use as a vapor barrier, sound attenuation, rain screen cladding, and air barrier.

It is available in numerous sizes, thicknesses, and finishes

Non-rusting, anti-corrosion band with a variety of casing options

Work on a range of weather conditions with a great look.

These are available in all shapes, sizes, colors, and Design

It is used in Architecture, Design, and Ventilation Systems in Residential and commercial.

Perforated Metal Pattern Options

The material affects the performance, durability and other factors of the perforated product.

Materials: Aluminum, Galvanized Steel, Stainless Steel, Copper, Brass, etc

Hole Size: 0.027″ - 1.0″

Hole Centres: 0.05″ - 1.25″

Hole Pattern: Straight rows, staggered and arbitrary patterns

Sheet Width: 24″ - 60″

Sheet Length: 24″ - 144″

Open Area: 5% - 63%

Materials: Aluminum, Galvanized Steel, Stainless Steel, Copper, Brass, etc

Hole Size: 0.2″ - 0.75″

Hole Centres: 0.5″ - 1″

Hole Pattern: Straight rows, staggered and arbitrary patterns

Sheet Width: 36″ - 48″

Sheet Length: 24″ - 120″

Thickness: 11 gauge - 22 gauge

Open Area: 11% - 56%

Materials: Aluminum, Galvanized Steel, Stainless Steel, Copper, Brass, etc

Slot Width: 0.125″ - 0.2″

Slot Length: 0.1″ - 0.75″

Slot Shape: Round end and square end

Slot Side Bar: 0.125″ - 0.25″

Slot End Bar: 0.125″ - 0.25″

Hole Pattern: Straight rows, staggered and arbitrary patterns

Sheet Width: 36″ - 48″

Sheet Length: 24″ - 120″

Thickness: 14 gauge - 22 gauge

Open Area: 41% - 74%

Materials: Aluminum, Galvanized Steel, Stainless Steel, Copper, Brass, etc

Hole Size: 0.25″ - 0.5″

Hole Centres: 0.2813″ - 0.5625″

Hole Pattern: Staggered row

Sheet Width: 25″ - 48″

Sheet Length: 24″ - 120″

Thickness: 11 gauge - 22 gauge

Open Area: 35% - 80%

With the aid of modern equipment and technology, the designs for decorative perforated metal are almost limitless.

From simple arrangements of common hole patterns to geometric shapes and even complex pattern designs. Any intricate and complex architectural design requirement can be accurately created with CAD drawing and computer-controlled software.

Precise perforation is then achieved on the sheet metal using advanced perforation equipment or laser equipment.

Perforated metal has a wide range of uses, whether in industry, construction, or everyday life.

The decoration of building facades increasingly needs to be creative and sustainable; simple materials and structures are no longer sufficient to meet the demands for aesthetic and high-end architecture. Perforated metal panels are an environmentally friendly decorative material that meets the requirements of most modern buildings. Especially when used as a building façade and cladding, it is a product that can combine function with aesthetics. If you are looking for such material for upgrading or redesigning a building project. Then perforated metal panels are definitely a solution that you should try.

Perforated Metal Ceiling Tiles

Using aluminum metal ceilings can improve the lighting in a room, as light reflecting from the walls and other surfaces pass through the holes of the roof and back into the room, mainly when daylight is limited.

Because it has several unique properties for construction projects, like easy installation and removal, modular design, easy maintenance, excellent fire prevention, sound absorption, etc., perforated metal ceiling tiles are distinctive from other materials.

Consider using perforated ceiling materials to add a modern touch when a place or space is designed or renovated.

Perforated Metal Stair Treads

Perforated metal sheets can also be used for stair treads. Safety, durability, cleanability, and aesthetics are its unique qualities.

Stairs are used for stepping, and especially in places with a large flow of people, the practicality of stairs is even more important. A simple slip or even a damaged tread can bring people's lives in danger, so the design of stairs should first consider its safety and durability.

Perforated metal stairs meet both of these needs well and are ideal for any indoor or outdoor staircase because of their unique features. It guarantees safety, enhances durability, reduces maintenance costs, and can be designed to enhance the visual appeal of the place.

Perforated Metal Fence Panels

From the structural point of view, the perforated metal fence is not much complicated, the post, frame, and perforated metal panel can form a set of fence. But it adds a charm to architectural projects that other traditional fences don't have.

Privacy, security, aesthetics, environmental adaptability, and more are all benefits of perforated metal fencing. All of these benefits come into play when incorporating perforated metal fencing into your residential or commercial property.

Perforated Metal Screen Panels

Perforated metal screens in most architectural applications provide different functions and diverse appearances. From the most intuitive decoration to hidden effects, perforated screens are the best material choice for many common functions of buildings.

Perforated Metal Wall Panels

Perforated metal wall panels are the need of the hour. Global architectural and technological advancements are forcing us to turn towards sustainable and eco-friendly materials.

The size of the holes in the decorative metal sheets can be customized according to the ventilation requirements of the architectural building. It also allows light, air and is also energy efficient.

Apart from their durability, long life service and sustainable nature, decorative metal panels consume little resources and gives more functionality.

Corrugated Perforated Metal Panels and Screen

Corrugated perforated metal panel is a design choice to obtain a more attractive appearance in architectural applications. It is manufactured by forming machines - ordinary flat perforated panels are processed into corrugated panels by forming machines. In addition to the attractive appearance, we offer corrugated perforated panels with improved strength and superior noise control.

Perforated Metal Speaker Grills

We know that the sound-optimizing properties of the perforated metal are popular in the construction sector. So did you know that it is also an essential material in acoustic equipment? For example, perforated metal speaker grilles seem to be seen in the sound outlets of many electronic devices.

Speaker grills made of perforated metal can improve the appearance and performance of audio equipment. It can protect the sensitive internal components of audio equipment from contamination and damage without preventing sound from being emitted.

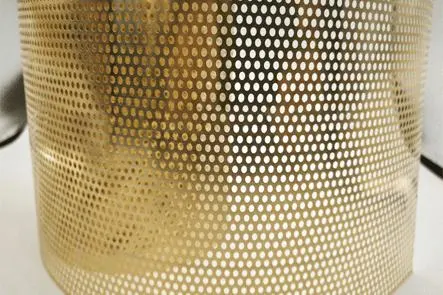

Perforated Metal Filter Tube

Perforated metal filters are made by machining perforated metal sheets into some specific shapes and then welding them by suitable welding methods. These filter components are most commonly made of stainless steel, but can also be made of aluminum, carbon steel and some alloy plates. They are then electrolytically polished (stainless steel), galvanized, sandblasted, pickled and passivated. This makes the surface smooth and flat and more resistant to corrosion.

Perforated Metal Cabinet Door Inserts

The kitchen is the center of the home, it is the place where all the warmth and satisfaction are centered. As you know, " Happiness is homemade "

And obviously, it is made in your kitchen where " The secret ingredient is always love"

So, we are supposed to give maximum importance to the kitchen and its essentials like kitchen cabinets. Numerous materials can be used to make customized kitchen cabinet door inserts including wood, plastic, metal, and a combination as well.

But whatever option you like, perforated metal cabinet door inserts are the most decorative and functional material option.

Dongfu Wire Mesh Company Profile

We were established as a factory in 2009 and registered as a company integrating manufacturing and trade in 2016. For more than 10 years, Dongfu Wire Mesh has been focusing on the production and research and development of metal wire mesh and steel products. Our vision is to be called the most customer-centric company to become China's largest metal product resource integrated supplier. Our products and services include Wire Mesh Cloth, Welded Mesh, Metal Bar Grating, Perforated Metal, Expanded Metal, Architectural Decorative Mesh, Temporary Fencing, Permanent Security Fence, Gabion Product, etc.

We are committed to providing customers in the metal industry with the best customer-centric services through high-quality products, competitive prices, reliable and fast delivery and stable supply capabilities, whether your requirement is large or small. 100% customer satisfaction is our ultimate goal.