Basic Info.

Model NO.

JY

Characteristic

Acid Resistance,Alkali Resistance,High Strenghth

Efficiency

40%----90%

Color

White

Size

Customerized

Transport Package

in Carton

Specification

Customized

Trademark

JOYE

Origin

Shanghai

HS Code

5911400000

Production Capacity

600000 Pieces/Year

Product Description

Features of Filter Cloth

1. Filter cloth is used for sludge dehydration in sewage treatment factories. They have the characteristics of good water permeability, air permeability and non-revealed sludge, acid-resisting, alkali-resisting, heat resistance (180°C) .Because of their designing structure, the sludge can be peeled off easily after pigeonhole filter, so the screen are easily cleaned and have a long working time. Therefore they are designed specially for sludge dehydration.

2.Filtration fabrics for belt filter presses are characterized by high strength, resistance against abrasion and high dimensional stability. Fabric construction secures good water drainage and at the same time protects the sludge cake form going through the fabric. Individual fabric designs differ in speed of dewatering, size of apertures, surface smoothness for easy cake release, resistance against abrasion, etc.

3. Fabrics for belt filter presses are equipped with stainless steel clipper seam and belt edges are melted. There is also the possibility to connect the fabric onto endless belt by using a woven seam, which is stronger and has a higher lifetime than clipper seam.

Application of Filter Cloth

Dewatering of municipal sludge in sewage plants

Dewatering of paper sludge and pulp

High pressure dewatering of pulp

Production of fruit and vegetable juices

Production of wine

Dewatering of minerals in mining industry

Dewatering of sand

Dewatering of sludge in agriculture

Other industrial separation processes

Technical Parameter of Different Kinds of the Filter Cloth

PP Filter Cloth 750B

PP Filter Cloth 840-1(A) (750A)

PP Filter Cloth 840-3

PP Filter Cloth 700AB

PP Filter Cloth 700A

Filter Cloth 120-7

Filter Cloth 822

Filter Cloth 621

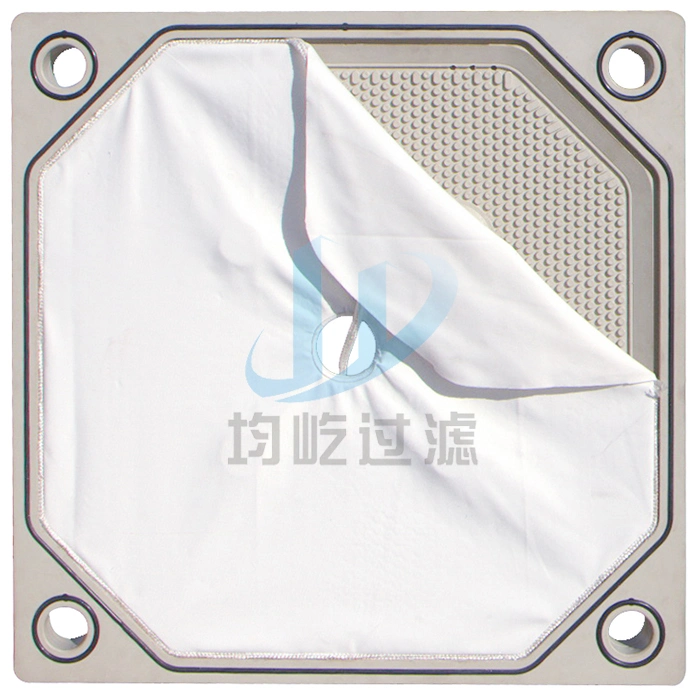

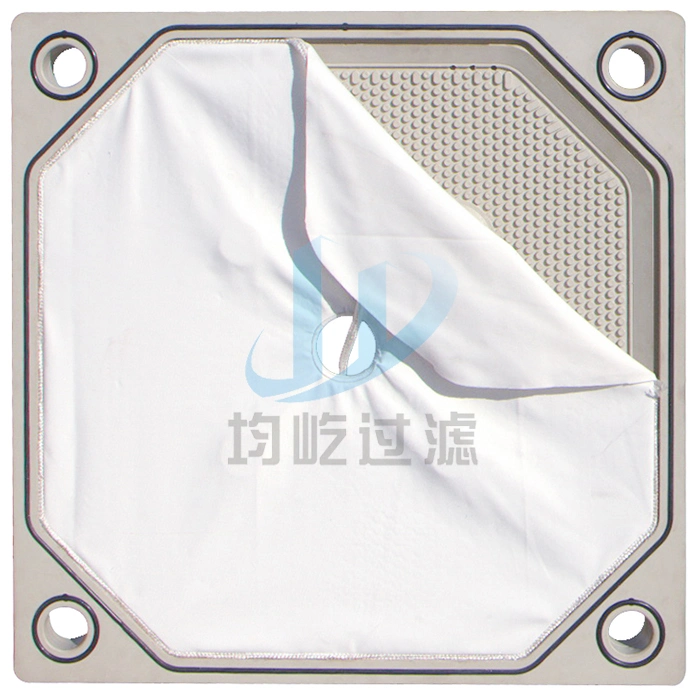

Filter Cloth installed on the Plate of Filter Press

Can we clean the cloths with a pressure sprayer?

You can, but take care to not get too close with the spray tip. Only use the sprayer in a "fan" spray pattern and keep spray pressure under 1000 PSI.

Can we clean cloths with chemical cleaners?

Polypropylene filter cloths can handle both caustic and acidic solutions. Nylon, polyester, and felt cloths need special consideration and may be damaged from these chemicals. Contact M.W. Watermark about your specific situation.

How can we extend our cloth life?

1) Filter cloth life is shortened by chemicals, mechanical wear, abrasion, and blinding. We can help to determine whether your cloths are being attacked by your process chemicals. Mechanical wear can be reduced by using a more durable cloth. Blinding often comes from "slamming" sludge into the press.

2) Consider an Auto Feed Pump Control System, or an AFPCS to automatically and gradually increase pressures. "Pre-coating" a press with DE or similar products can also add substantial life to cloths. The coating protects against wear and minimizes blinding.

Shippment and Term of Payment

Our Working

Contact Us

1. Filter cloth is used for sludge dehydration in sewage treatment factories. They have the characteristics of good water permeability, air permeability and non-revealed sludge, acid-resisting, alkali-resisting, heat resistance (180°C) .Because of their designing structure, the sludge can be peeled off easily after pigeonhole filter, so the screen are easily cleaned and have a long working time. Therefore they are designed specially for sludge dehydration.

2.Filtration fabrics for belt filter presses are characterized by high strength, resistance against abrasion and high dimensional stability. Fabric construction secures good water drainage and at the same time protects the sludge cake form going through the fabric. Individual fabric designs differ in speed of dewatering, size of apertures, surface smoothness for easy cake release, resistance against abrasion, etc.

3. Fabrics for belt filter presses are equipped with stainless steel clipper seam and belt edges are melted. There is also the possibility to connect the fabric onto endless belt by using a woven seam, which is stronger and has a higher lifetime than clipper seam.

Application of Filter Cloth

Dewatering of municipal sludge in sewage plants

Dewatering of paper sludge and pulp

High pressure dewatering of pulp

Production of fruit and vegetable juices

Production of wine

Dewatering of minerals in mining industry

Dewatering of sand

Dewatering of sludge in agriculture

Other industrial separation processes

Technical Parameter of Different Kinds of the Filter Cloth

PP Filter Cloth 750B

| Material | PP | The type | 750B |

| Technology | Single layer | Weave method | twill |

| Nature | acid/alkali-resisting Thickness | 0.88mm | |

| Air perm | 35(L/m2·s) | Unit weight | 450-460 (g/m2) |

| Warp density | 268 (root/10cm) | Weft density | 157 (root/10cm) |

| With or without the filter material | Without | ||

PP Filter Cloth 840-1(A) (750A)

| Material | PP | The type | Multifilament |

| Technology | Double layer | Weave method | Plain |

| Nature | alkali/heat/cold-resisting, water proof Thickness | 0.88mm | |

| Air perm | 35(L/m2·s) | Unit weight | 471 (g/m2) |

| Application | Dust | Air clear | |

PP Filter Cloth 840-3

| Material | PP | The type | Multifilament |

| Technology | Double layer | Weave method | One Plain/one Twill |

| Nature | acid /alkali /heat -resisting Thickness | 1.36mm | |

| Air perm | 111.6(L/m2·s) | Unit weight | 500 (g/m2) |

| Application | Coal dressing | Air clear | |

| Warp density | 333 (root/10cm) | Weft density | 204 (root/10cm) |

| Application | Dust | Air clear | |

PP Filter Cloth 700AB

| Material | PP | The type | 700AB |

| Technology | Double layer | Weave method | Plain |

| Nature | acid /alkali /cold -resisting Application | Sludge | |

| Application | Water processing | filter | |

PP Filter Cloth 700A

| Material | PP | The type | 700A |

| Technology | ** | Weave method | Plain |

| Nature | acid /alkali -resisting Thickness | 0.7mm | |

| Air perm | 11.79(L/m2-s) | Unit weight | 350(g/m2) |

| Warp density | 204 (root/10cm) | Weft density | 106 (root/10cm) |

Filter Cloth 120-7

| Material | PE | The type | 120-7 |

| Technology | Sigel layer | Weave | Twill |

| Nature | acid /alkali /heat/cold -resisting Thickness | 1.42mm | |

| Air perm | 54(L/m2·s) | Unit weight | 610(g/m2) |

Filter Cloth 822

| Material | PE | The type | 120-7 |

| Technology Sigel double layer | Weave Plain,Twill | ||

| Nature | acid /alkali /heat/cold -resisting Thickness | 0.5mm | |

| Air perm | 100(L/m2·s) | Unit weight | 600(g/m2) |

| Warp density | 30 (root/10cm) | Weft density | 27 (root/10cm) |

Filter Cloth 621

| Material | PE | The type | Multifilament |

| Technology | Sigel layer | Weave | Plain |

| Thickness | 0.63mm | ||

| Air perm | 11.34(L/m2·s) | Unit weight | 390(g/m2) |

| Warp density | 188 (root/10cm) | Weft density | 137 (root/10cm) |

Filter Cloth installed on the Plate of Filter Press

Can we clean the cloths with a pressure sprayer?

You can, but take care to not get too close with the spray tip. Only use the sprayer in a "fan" spray pattern and keep spray pressure under 1000 PSI.

Can we clean cloths with chemical cleaners?

Polypropylene filter cloths can handle both caustic and acidic solutions. Nylon, polyester, and felt cloths need special consideration and may be damaged from these chemicals. Contact M.W. Watermark about your specific situation.

How can we extend our cloth life?

1) Filter cloth life is shortened by chemicals, mechanical wear, abrasion, and blinding. We can help to determine whether your cloths are being attacked by your process chemicals. Mechanical wear can be reduced by using a more durable cloth. Blinding often comes from "slamming" sludge into the press.

2) Consider an Auto Feed Pump Control System, or an AFPCS to automatically and gradually increase pressures. "Pre-coating" a press with DE or similar products can also add substantial life to cloths. The coating protects against wear and minimizes blinding.

Shippment and Term of Payment

Our Working

Contact Us